Product No: SMT-PA100A

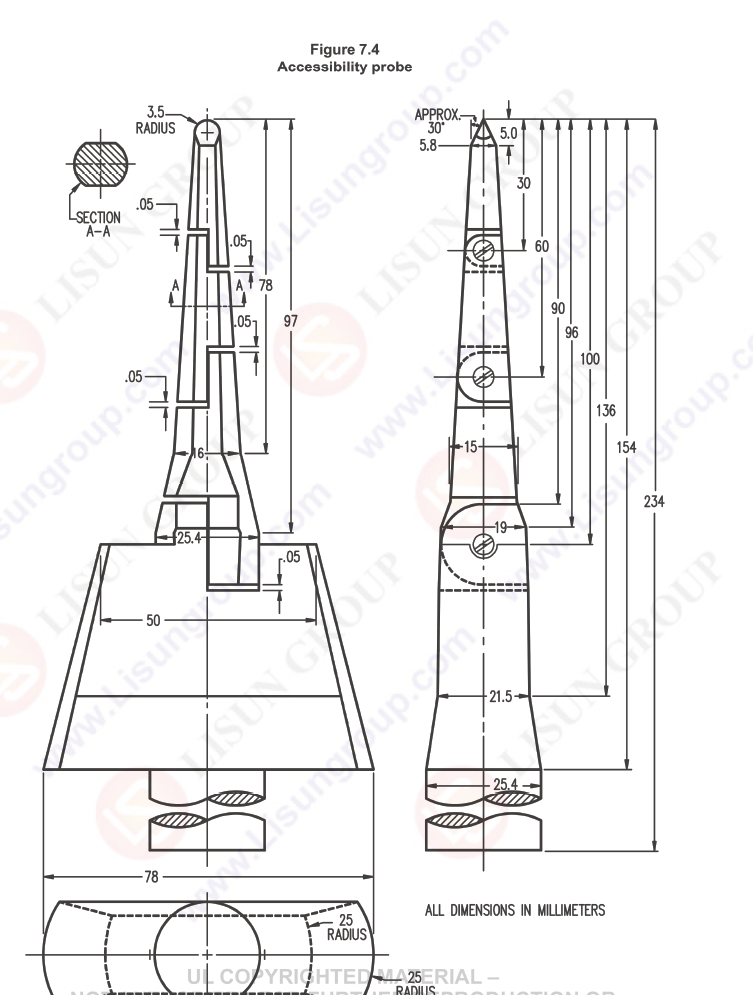

The Accessibility Probe of UL 639 Figure 7.4 is a specialized safety tool engineered for testing access to hazardous live parts or moving components in electric kitchen appliances—such as countertop ovens, electric skillets, and food processors. It features a narrow 6mm conductive brass tip to navigate tight gaps (e.g., between control knobs or heating element covers) and a 38mm circular stop face to prevent over-insertion. Paired with an insulated nylon handle for operator safety, it applies a controlled 15N thrust to mimic accidental user contact. Strictly compliant with UL 639, it’s critical for manufacturers to validate appliance safety and avoid electric shock or injury risks.

Specifications:

Tool Type: Accessibility Probe (UL 639 Figure 7.4; for hazardous part testing in electric kitchen appliances)

Material: stainless steel and nylon

Key Dimensions:

– Test finger diameter: 25.4 mm (1 inch)

– Test finger length: 101.6 mm (4 inch)

– Head radius: R12.7 mm (1/42 inch)

– Tail diameter: 31.75 mm (1-1/4 inch)

Applied Thrust: 15N ± 1N (simulates accidental user contact with kitchen appliances; aligns with UL 639 requirements)

Core Function: Tests access to hazardous live/moving parts in kitchen appliances; prevents over-insertion via stop face; ensures UL compliance

Test Procedures:

1. Inspect the probe for bent tips, cracked insulation, or loose stop faces; confirm conductivity with a test tool.

2. Power on the kitchen appliance under test (EUT, e.g., electric skillet) and set it to normal operating mode.

3. Hold the insulated handle, align the 6mm tip with EUT gaps (control knob seams, heating element covers).

4. Apply steady 15N thrust to advance the probe—stop if the 38mm stop face touches the EUT.

5. Check the connected live-part detector for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if the probe reaches dangerous components.

Applications:

1. Testing access to heating element terminals in countertop ovens (per UL 639:2023 Figure 7.4) to prevent electric shock.

2. Verifying control panel gaps in electric skillets (compliant with UL 60335-1:2023) to block contact with internal wiring.

3. Safety checks for food processor blade housing seams (per UL 639-2-1:2023) to avoid injury from moving parts.

4. Quality control for electric grills during manufacturing, ensuring UL 639 compliance for hazardous part protection.

5. Post-production testing of toaster oven door hinges to meet global electric kitchen appliance safety standards.

Accessibility Probe of UL 639 Figure 7.4