Product No: SMT-5753

Test Finger for EN 50075 Figure 3 is a dedicated tool for verifying the structural and dimensional compliance of flat, non-rewirable two-pole plugs and sockets (for 2.5A 250V Class II household equipment). Compliant with BS EN 50075 Figure 3, it features heat-treated steel construction for durability and two joints that bend 90° (with 0~+10° tolerance) in one direction—mimicking real human finger movement. An insulating handle and precision-machined stop plate prevent over-insertion, ensuring accurate testing of whether plugs/sockets block access to hazardous parts. It’s essential for electronics and appliance industries.

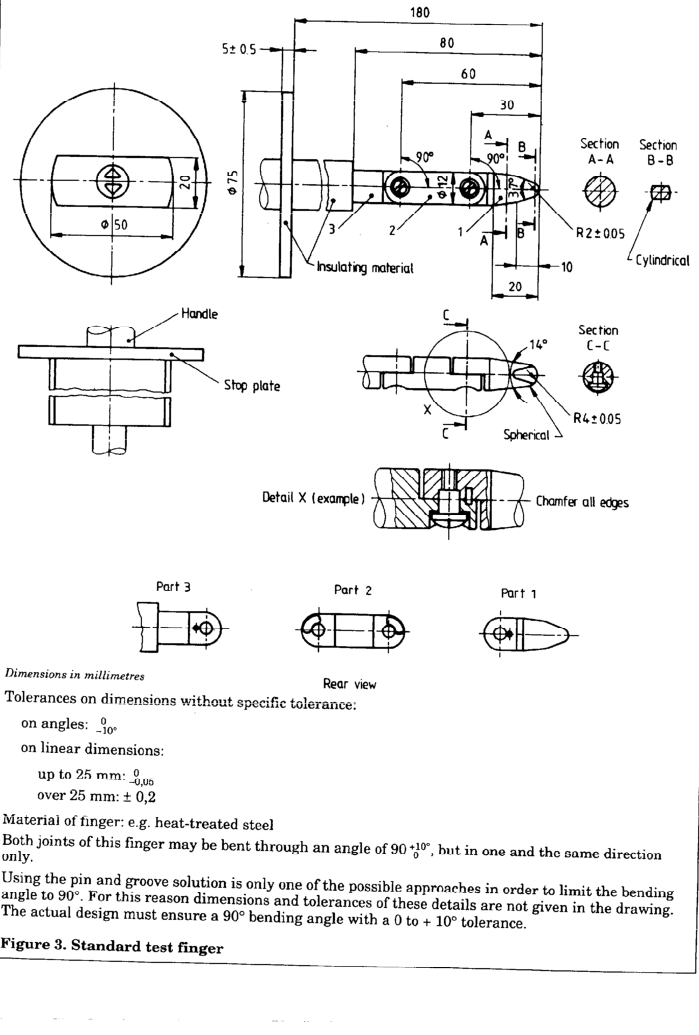

Specifications:

• Overall Length: 180mm (covers typical plug/socket access depths)

• Key Precision Dimensions: 5±0.5mm (critical contact section); 80mm, 60mm, 30mm (segment lengths)

• Bending Performance: Two joints, bendable to 90° (tolerance: 0~+10°) in a single direction

• Tolerances – Angles: ±10°; – Linear dimensions ≤25mm: ±0.1mm; >25mm: ±0.2mm

• Material Test finger: Heat-treated steel (wear-resistant, maintains shape); Handle: Insulating material (user safety protection)

• Structural Features: Spherical tip (R4±0.05mm); Cylindrical section (R2±0.05mm); All edges chamfered (prevents sample damage)

Test Procedures:

• Inspect the test finger for bent joints, rust, or cracked insulation; confirm bending angle and dimensions meet specs.

• Power off the plug/socket under test and place it on a stable, flat surface.

• Bend the test finger’s joints to 90° (within 0~+10° tolerance) to match real finger access angles.

• Hold the insulating handle, align the spherical tip with gaps in the plug/socket, and gently insert until the stop plate touches the surface.

• Check if the finger can reach hazardous parts (e.g., live pins) inside the plug/socket.

• Record results to verify compliance with BS EN 50075:1990 Figure 3.

Applications:

• Safety testing of flat non-rewirable two-pole plugs for Class II household appliances (e.g., electric irons, small coffee makers) per BS EN 50075.

• Dimensional and structural checks for socket-outlets paired with Class II equipment plugs (e.g., desk lamps, portable fans).

• Quality control for plug/socket manufacturers to ensure production consistency and safety.

• Third-party certification testing (e.g., CE, GS) for plugs/sockets entering EU/UK markets.

• R&D validation for new plug/socket designs, ensuring they block hazardous part access before mass production.

Test Finger with EN 50075 Figure 3 Standard