Product No: SMT-SM208

This UL 1278 Fig 10.3 Triangle Probe is a specialized safety tool engineered for portable electric tools—such as angle grinders, circular saws, and jigsaws. Its unique triangular stainless steel tip is designed to access ultra-narrow gaps (e.g., between tool guards and blades, or around switch housings) that standard round probes can’t reach. Paired with an insulating nylon handle for tester safety to mimic accidental contact, verifying if hazardous moving parts (e.g., blade shafts, gears) or live components remain inaccessible.

Specifications:

Probe Type: UL 1278 Fig 10.3 Triangle Probe (for portable electric tool narrow-gap testing)

Tip Material: Stainless steel (rigid, corrosion-resistant)

Handle Material: Nylon (fully insulating, heat-resistant up to 100°C; non-slip grip for precise gap insertion)

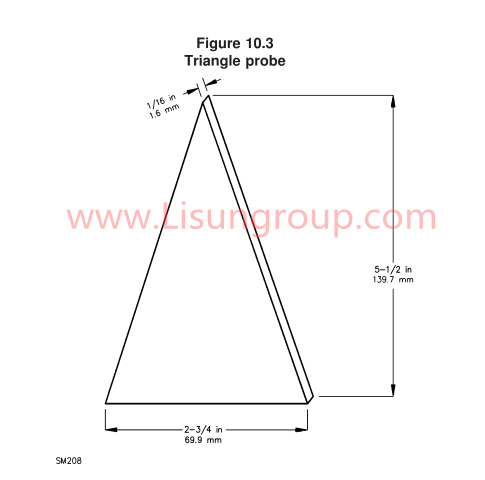

Key Dimensions:

– Triangle Base Length: 69.9mm

– Triangle Height: 139.7mm

– Probe Thickness: 1.6mm

Test Procedures:

1. Inspect the probe for damage (bent tip, cracked handle) and confirm triangular shape integrity.

2. Power on the electric tool and activate its moving components (e.g., saw blade, grinder wheel).

3. Hold the insulating handle and align the triangle tip with ultra-narrow gaps (e.g., guard-blade seams).

4. Apply steady 10N thrust to the probe—stop if resistance from internal parts is felt.

5. Check if the tip touches moving components (blades, gears) or live wires.

6. Record pass/fail results and power off the tool.

Applications:

1. Safety testing of angle grinder guard-blade gaps (per UL 1278:2023 Fig 10.3) to block gear access.

2. Verification of jigsaw blade guide gaps to prevent contact with moving linkage parts.

3. Quality control for belt sanders (narrow guard gaps around sanding belts) during manufacturing.

4. Post-production audits of reciprocating saws to meet U.S. UL 1278 narrow-gap safety standards.

Triangle Probe of UL1278 Fig.10.3