Product No: SMT-1211C

This IEC 61032 Figure 7 Test Probe 11 with cable is an unjointed rigid finger tool designed to simulate human finger contact, verifying accessibility to hazardous live parts in electrical equipment. Equipped with an integrated cable for electrical continuity testing, it features a durable stainless steel probe (chrome-plated for corrosion resistance) and a polyamide insulating handle for user safety. Fully compliant with global standards like IEC 61032, it’s ideal for checking enclosure protection and mechanical stability of equipment openings—making it essential for manufacturers, labs, and certifiers validating electrical safety.

Specifications:

• Probe Design: Unjointed rigid finger (simulates human finger movement for realistic testing)

• Material Composition – Probe: Stainless steel (chrome-plated finish, corrosion-resistant); – Handle: Polyamide (insulating, flame-retardant UL94 V-0 rating)

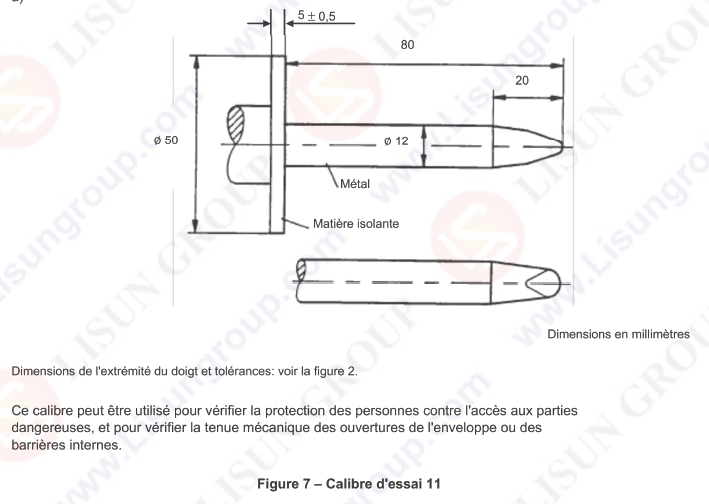

• Key Dimensions – Probe diameter: ø12mm; – Baffle plate diameter: ø50mm; – Length (probe + handle): 80mm; – Tip-related dimension: 5±0.5mm (aligns with IEC 61032 Figure 7)

• Cable Functionality: Integrated cable for electrical continuity testing (verifies contact with live parts)

• Surface Finish: Chrome plating (enhances wear resistance and extends service life)

• Dimensional Tolerances: Linear dimensions ≤25mm: ±0.1mm; >25mm: ±0.2mm; Diameters: ±0.05mm

• Compatibility: Works with household, commercial, and low-voltage industrial electrical equipment.

Test Procedures:

• Inspect the probe for bent stainless steel, cracked handles, or damaged cables; confirm dimensions and plating integrity.

• Power off the equipment under test and secure it on a flat, stable surface.

• Connect the probe’s cable to a continuity tester (if verifying live part contact).

• Hold the polyamide handle, align the rigid probe with target openings (e.g., vents, control gaps).

• Gently insert the probe to check if it reaches hazardous parts; use the continuity tester to confirm contact (if applicable).

• Record results to verify compliance with safety standards.

Applications:

• Accessibility testing of hazardous live parts in household appliances (e.g., washing machines, ovens).

• IP Code enclosure verification (e.g., checking dust/water protection gaps).

• Safety checks for industrial control panels (low-voltage).

• UL certification testing of small kitchen appliances (e.g., blenders, toasters).

• Mechanical stability checks of equipment openings (e.g., TV casings, audio speakers) using IEC 61032 Test Probe 11.

Test Probe 11 with Cable with Figure 7 of the IEC 61032