Product No: SMT-IP20T

The 635mm Steel Test Ball (Without Ring) is a heavy-duty impact testing tool built for large, robust equipment enclosures—such as industrial machinery frames, commercial walk-in refrigerators, and data center server cabinets. Crafted from solid carbon steel, its extra-large 635mm diameter delivers high-impact force to simulate extreme real-world scenarios (e.g., falling heavy objects or industrial collisions). The “without ring” design optimizes it for fixed test benches (no suspension needed), ensuring stable placement and consistent impact during testing. It verifies if enclosures resist cracking, deformation, or exposure of hazardous internal parts (e.g., high-voltage components), making it critical for manufacturers to validate heavy-equipment safety and meet global standards.

Standards:

| Standards No. | Clause/Figure | Standards Name |

| IEC 60529:2013 | Clause 9.5, Figure 9.5 | Degrees of protection provided by enclosures (IP Code) – Impact resistance testing |

| UL 1989:2023 | Clause 5.2.5, Figure 5.2.5 | Standard for Safety for Information Technology Equipment – Impact Test Requirements |

| EN ISO 12100:2010 | Clause 5.4, Figure 5.4 | Safety of machinery – General principles for design – Risk assessment and risk reduction |

Specifications:

Tool Type: 635mm Steel Test Ball (Without Ring; for heavy-duty equipment enclosure impact testing)

Material: Solid carbon steel (density: 7.85g/cm³; high rigidity, no deformation under high impact; corrosion-resistant)

Key Dimensions:

– Diameter: 635mm ± 0.5mm

– Calculated Weight: ~1050kg ± 20kg (based on spherical volume formula: (4/3)πr³ × material density)

Surface Treatment: Smooth, deburred finish (prevents artificial scratches on test enclosures; ensures even impact force distribution)

Typical Impact Height: 1.5–2.5 meters (adjustable per heavy-equipment category; specified in IEC/UL/EN standards)

Core Function: Delivers high-impact force to test structural integrity of heavy-duty enclosures; verifies no hazardous part exposure post-impact

Test Procedures:

1. Inspect the steel ball for damage (dents, cracks, rough surfaces) to confirm test accuracy.

2. Secure the heavy-duty equipment under test (EUT) on a reinforced, non-slip test bench.

3. Adjust the test setup to the specified impact height (e.g., 2.0m for industrial machinery).

4. Place the steel ball at the target height (using a fixed lifting mechanism) and release it freely.

5. After impact, visually inspect the EUT enclosure for cracks, deformation, or loose components.

6. Record results: Pass if enclosure remains intact; Fail if damage or hazard exposure occurs.

Applications:

1. Impact testing of heavy industrial machinery enclosures (e.g., factory presses) per IEC 60529:2013 Figure 9.5.

2. Safety verification of large commercial walk-in refrigerator shells (compliant with UL 1989:2023) to resist collision damage.

3. Structural checks for data center server cabinet exteriors (resisting heavy object drops) per EN ISO 12100:2010.

4. Quality control for industrial power distribution cabinet enclosures during manufacturing.

5. Post-production testing of large-scale energy storage system (ESS) outer casings to meet global heavy-equipment safety standards.

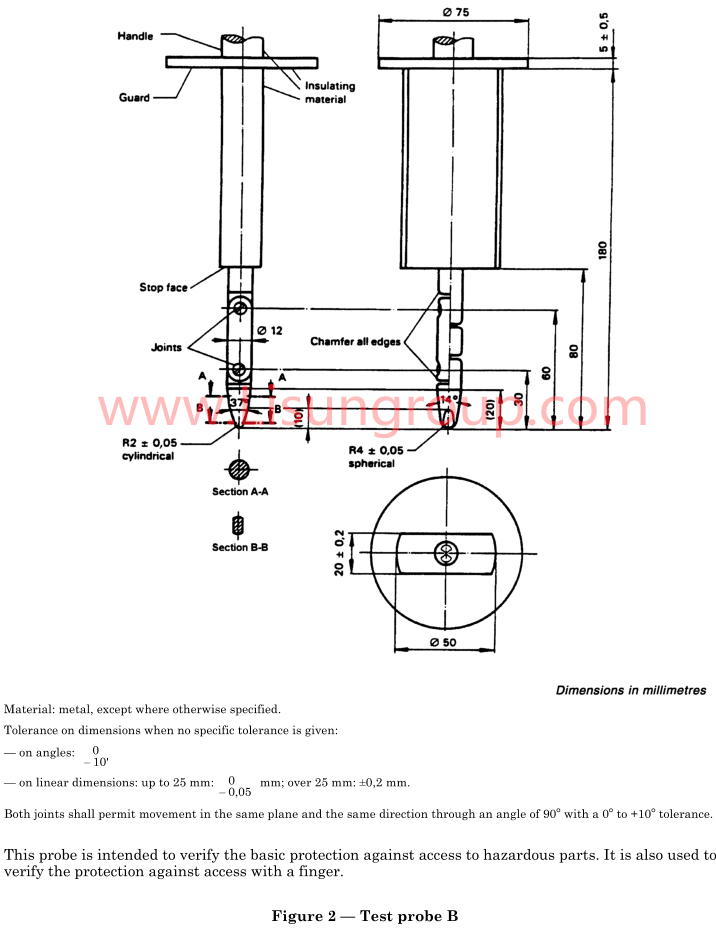

IEC 61032 ArticUL ating Finger Probe with Dynamometer 10N