Product No: SMT-CT3

The IEC 61032 Figure 3 IP3X Trust Test Probe C is a precision safety tool built for testing household, office, and small industrial appliances—like refrigerators, washing machines, and coffee makers. Its slim 2.5mm metal rod targets narrow openings (vents, control gaps, or button seams) to verify if hazardous live parts (e.g., wiring, terminals) are accessible. The 35mm insulating baffle prevents over-insertion, while the fixed 3N thrust mimics light tool-like contact (critical for consistent IP3X protection testing). Crafted from corrosion-resistant steel and paired with an ergonomic insulated handle, it meets global safety standards, making it essential for manufacturers to prevent electric shock and validate appliance safety.

Specifications:

Tool Type: IEC 61032 Figure 3 IP3X Trust Test Probe C (IEC 61032 compliant; for IP3X foreign body/hazardous part testing)

Rod Material: Conductive stainless steel (resistance ≤ 0.1Ω; corrosion-resistant; rigid, no deformation under 3N force)

Handle/Baffle Material: Insulated ABS plastic (handle resistance ≥ 100MΩ; heat-resistant up to 110°C; baffle for over-insertion protection)

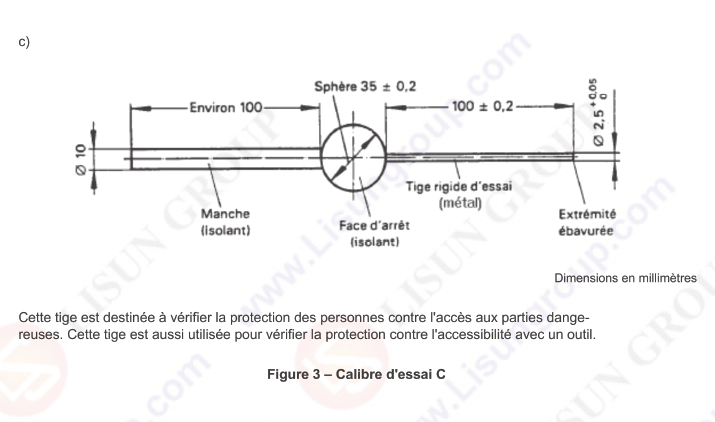

Key Dimensions:

– Rod length: 100 mm

– Rod diameter: 2.5 mm

– Circular-baffle diameter: 35 mm

– Handle diameter: 10 mm

– Handle length: 100 mm

– Thrust: 3N

Applied Thrust: 3N ± 0.3N (fixed; simulates light tool contact; no external dynamometer needed)

Core Function: Tests IP3X protection by verifying narrow openings block 2.5mm objects; detects accessible hazardous live parts in appliances

Test Procedures:

1. Inspect the probe for damage (bent rod, cracked insulation, loose baffle) and confirm conductivity with a test tool.

2. Secure the appliance under test (EUT) on a flat, stable surface—power it on to normal operating mode.

3. Hold the insulated handle, align the 2.5mm rod with the EUT’s narrow openings (e.g., vent slots, control gaps).

4. Apply steady 3N thrust to advance the rod; stop if the baffle touches the EUT or resistance is felt.

5. Check the connected live-part detector for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact/blocked by baffle; Fail if rod reaches live parts.

Applications:

1. Testing ventilation gaps in household refrigerators (per IEC 60529:2013) to block access to live cooling system wiring.

2. Verifying button seams in coffee makers (compliant with UL 60335-1:2023) to prevent electric shock from internal circuits.

3. Safety checks for washing machine control panel slots (per IEC 61032) to avoid contact with motor terminals.

4. Quality control for office printer USB port gaps during manufacturing, ensuring IP3X foreign body protection.

5. Post-production testing of small air conditioner side vents to meet global appliance safety rules.

3N Thrust IP3X Test Probe Pin IEC 61032