Product No: SMT-B125T

The IEC 61032 Figure 6 with 30N Force 12.5mm Test Sphere Probe is a rugged safety tool built to verify if equipment enclosures block solid foreign objects 12.5mm or larger—critical for preventing debris, small tools, or accidental touches from damaging internal components (e.g., circuits, motors) or exposing hazards. Crafted from high-strength bearing steel (for durability and consistent shape), it delivers a controlled 30N thrust to mimic real-world pressure (like a light push with a small object). It fits household, industrial, and electronic equipment testing needs, strictly complying with IEC 61032, making it a must-have for manufacturers validating enclosure safety and meeting global IP protection standards.

Standards:

| Standards No. | Clause/Figure | Standards Name |

| IEC 61032:2017 | Clause 5.2, Figure 6 | Test probes for protection against access to hazardous parts |

| IEC 60529:2013 | Clause 8.4, Figure 8.4 | Degrees of protection provided by enclosures (IP Code) – Foreign body protection testing |

| UL 60335-1:2023 | Clause 22.4, Figure 22.4 | Standard for Safety for Household and Similar Electrical Appliances – Part 1: General Requirements |

| IEC 60065:2021 | Clause 9.3, Figure 9.3 | Audio, video and similar electronic apparatus – Safety requirements |

Specifications:

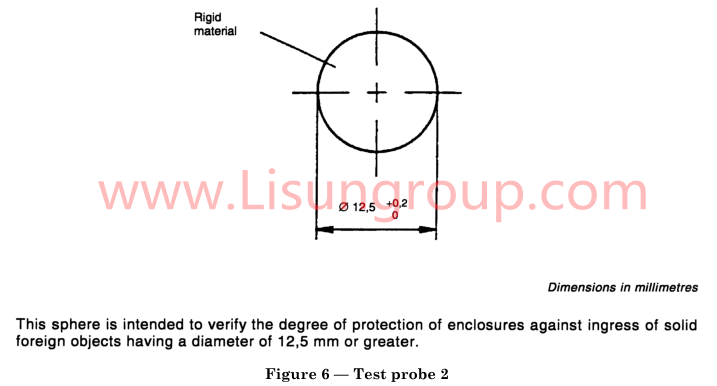

Tool Type: IEC 61032 Figure 6 with 30N Force 12.5mm Test Sphere Probe (IEC 61032 compliant; for 12.5mm+ foreign body enclosure testing)

Sphere Material: Bearing steel (high rigidity, no deformation under 30N force; corrosion-resistant; density: 7.85g/cm³)

Key Dimensions:

– Sphere Diameter: 12.5mm ± 0.1mm

– Optional Mounting: Threaded base (for test stand attachment; length: 50mm ± 0.5mm if included)

Applied Thrust: 30N ± 3N (standard for IEC/UL testing; simulates light real-world pressure from small objects)

Surface Treatment: Smooth, deburred finish (prevents scratches on tested enclosures; ensures even force distribution)

Core Function: Verifies enclosures block 12.5mm+ solid foreign objects; prevents intrusion damage/hazard exposure; ensures IEC 61032 compliance

Test Procedures:

1. Inspect the test sphere for dents, cracks, or rough edges—confirm it retains a perfect spherical shape.

2. Secure the equipment under test (EUT, e.g., a washing machine) on a flat, non-slip surface.

3. Align the 12.5mm sphere with the EUT’s target openings (vents, control panel seams, or cable entry gaps).

4. Apply a steady 30N force to push the sphere toward the opening; stop if resistance blocks further movement.

5. Check if the sphere penetrates the enclosure (signaling a failure) or stays outside (a pass).

6. Record results: Pass if no intrusion; Fail if the sphere enters the EUT.

Applications:

1. Testing vent gaps in household dryers (per IEC 61032:2017 Figure 6) to block 12.5mm debris from hitting heating elements.

2. Verifying industrial motor control box seams (compliant with IEC 60529:2013) to prevent small tool intrusion.

3. Safety checks for audio amplifier enclosure slots (per IEC 60065:2021) to avoid dust/object damage to internal circuits.

4. Quality control for portable air conditioner side vents during manufacturing, ensuring 12.5mm object protection.

5. Post-production testing of office printer outer casings (per UL 60335-1:2023) to meet global appliance safety rules.

30N Force 12.5mm Test Sphere Probe IEC 61032