Product No: GNGPL-98181

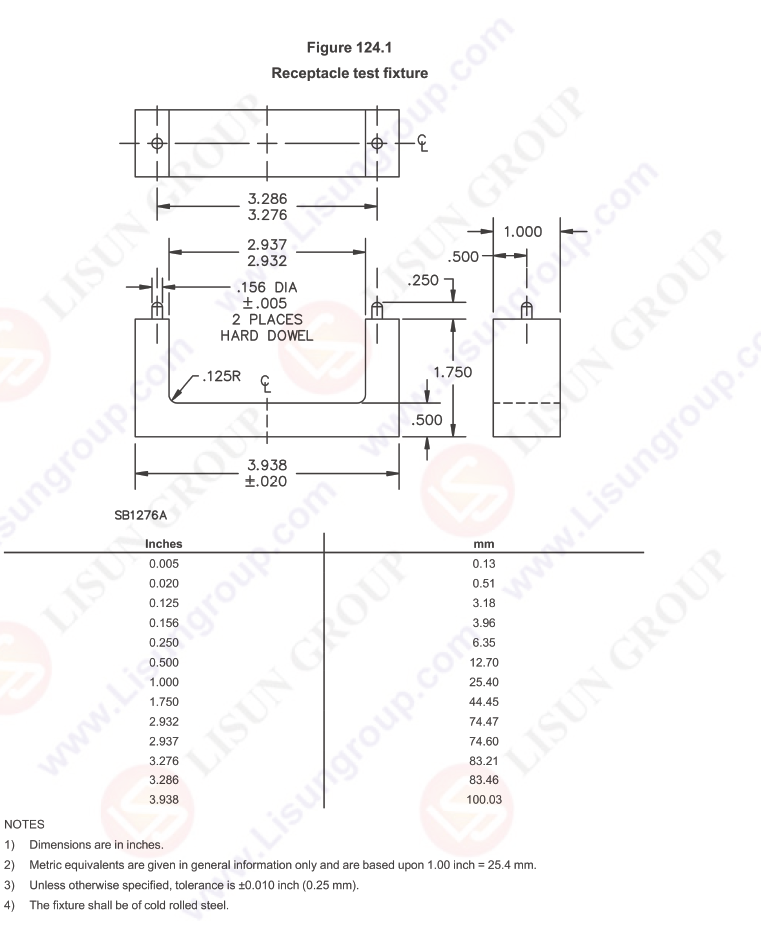

Receptacle Test Fixture SB1276A of UL 498 Figure 124.1 manufactured in strict accordance with UL 498 Figure 124.1 standard, specifically designed for verifying the structural rationality and dimensional accuracy of plugs and sockets. It fully complies with all the technical specifications and performance requirements of the relevant standard, with its core parameters such as material hardness, dimensional tolerance and surface roughness all meeting industry benchmark levels. The fixture features a small thermal expansion coefficient, which ensures that its dimensions and tolerances remain stable and reliable under various working conditions, making it an essential testing tool for manufacturers, third-party certification institutions and related enterprises to carry out compliance testing and quality control on plug and socket products, and effectively helping to ensure that the tested products meet the safety and quality requirements specified in UL 498 standard.

Specifications

• Complies with the technical requirements of UL 498 Figure 124.1 standard

• Material hardness reaches no less than 50HRC for excellent wear resistance and structural stability

• Has a small thermal expansion coefficient to maintain consistent dimensions and tolerances in different environments

• Dimensional parameters and tolerances are strictly calibrated to match standard specifications

• Surface roughness meets the specified indicators of relevant industry standards

• Adopts high-quality materials to ensure long-term testing durability and precision

• Structural design conforms to standard testing operation requirements for convenient and accurate detection

Test Procedures

• Prepare the receptacle test fixture and the plugs or sockets to be tested, and ensure that both the tool and the tested products are free of dirt, deformation or other defects that may affect the test results.

• Refer to the operation guidelines of UL 498 Figure 124.1 to accurately position the fixture and align it with the target detection area of the plug or socket.

• Gently fit the tested product into the corresponding position of the fixture, and check the structural fit and dimensional compliance of the product through the fixture’s detection structure.

• Record all test data and judgment results in detail, including the fit status of the product and the compliance of key dimensions with the standard.

• After completing the test, clean the fixture with a professional cleaning tool to remove surface impurities, and store it in a dedicated protective container to prevent damage and ensure the accuracy of subsequent tests.

Applications

• Production line quality inspection of plug and socket products in electrical component manufacturing plants to verify structural and dimensional compliance

• Compliance certification testing of electrical connection devices for third-party testing and certification institutions

• Quality verification of plug and socket accessories in the electronics and electrical appliance manufacturing industries

• Structural design validation for new types of plug and socket products in the R&D phase of electrical equipment enterprises

• Routine safety and quality inspection of plug and socket components during the maintenance and upgrade of engineering electrical systems

Receptacle Test Fixture SB1276A of UL 498 Figure 124.1