Product No: LS-B64

The LS-B64 Buried Conduit Impact Testing Device is a professional impact performance testing equipment designed for buried conduits and related accessories. It simulates the impact conditions that conduits may experience in underground environments, and, combined with specific pretreatment procedures and impact methods, accurately verifies the impact resistance and structural integrity of conduits and accessories. The device employs a robust structural design to ensure accurate positioning and stable stress during the test, and can strictly follow standardized procedures to complete impact tests. It helps users determine whether conduit products meet the requirements for underground installation scenarios, providing reliable support for the quality inspection and compliance verification of buried conduits. The operating procedures closely match testing needs, and the results are accurate and reliable.

Standards:

| Standards No. | Standards Name |

| IEC/EN 61386-24:2021 | Conduit systems for electrical installations – Part 24: Particular requirements for rigid conduits and fittings for underground use |

| GB 20041.24-2019 | 电气安装用导管系统 第 24 部分:埋入地下的刚性导管及配件的特殊要求 |

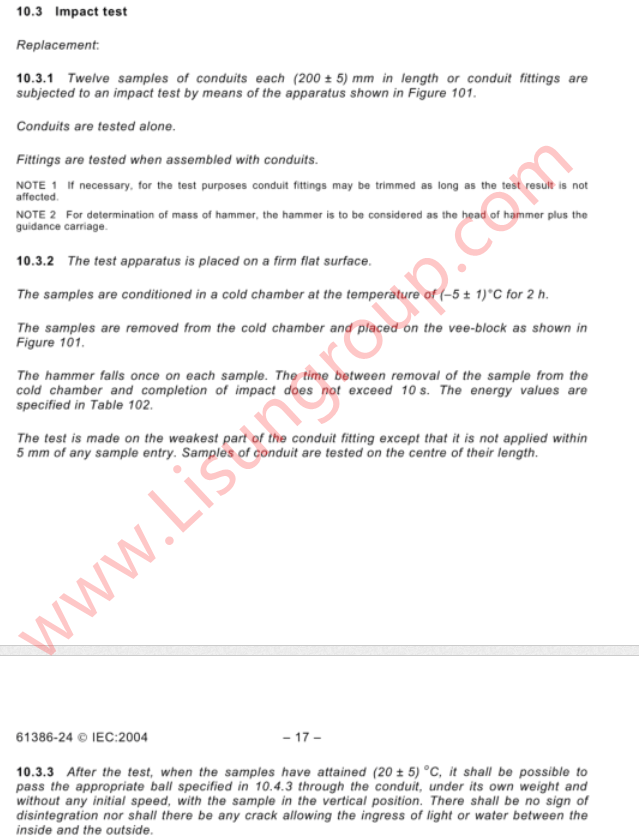

Sample preparation: Take 12 samples of conduits or conduit accessories with a length of (200±5) mm. The conduits are tested separately, and the accessories are tested after being assembled with the conduits. If necessary, the accessories can be trimmed (without affecting the results). Determine the mass of the heavy hammer including the head and the guide device.

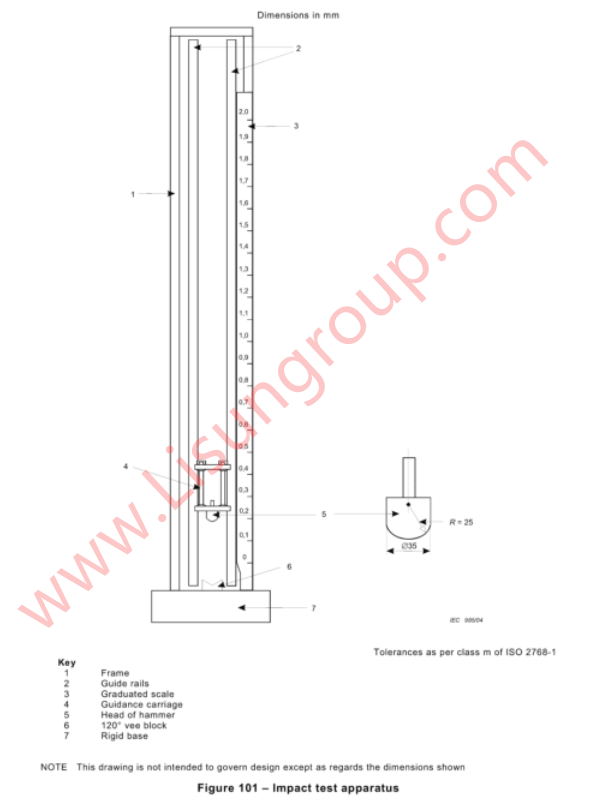

Test conditions: The test device is placed on a solid plane, and the samples are pretreated in a (-5±1)℃ cold box for 2 hours. After being taken out, a V-shaped block is placed (see Figure 101). The time from taking out the cold box to the completion of the impact is ≤10 seconds.

Test operation: The heavy hammer impacts each sample once, and the energy value refers to Table 102; the accessories are tested at the weakest point (≥5mm from the entrance), and the conduit is tested at the center of the length.

Clause 10.3 of standard EN 61386-24:2011

Figure 101 of standard EN 61386-24:2011