Product No: GNGPL-6215

This DIN-VDE 0620-1-Lehre 15 Prüfung der Nichtberührbarkeit von aktiven Teilen durch die Shutter hindurch nach der Prüfung des bestimmungsgemäßen Betriebs is dedicated to testing the non-accessibility of live parts through the shutters of sockets after they have undergone normal operation testing, in strict compliance with the DIN VDE 0620 series standards. It is a crucial safety verification tool for fixed sockets used in household and similar applications, ensuring that the shutter mechanism retains its protective function even after regular use, preventing unintended access to live components and mitigating electrical shock risks.

Specifications:

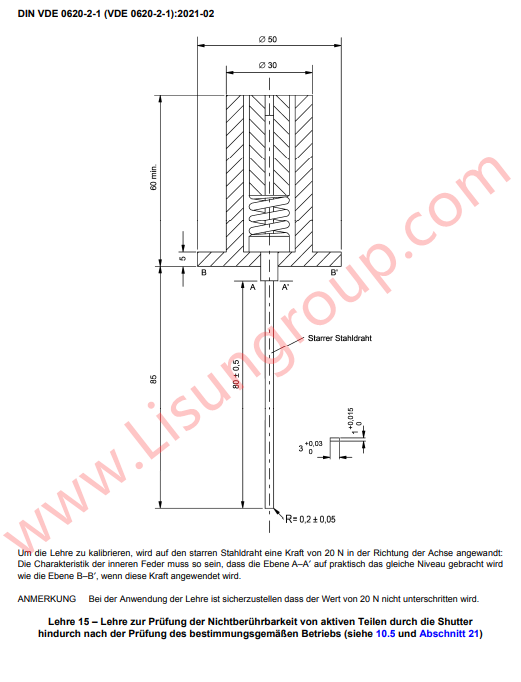

• Complies with DIN VDE 0620-1 and DIN VDE 0620-2-1:2021-02 standards

• Material: Rigid steel wire (Starrer Stahldraht)

• Dimensions: ø50, ø30, 3+0.03

• Length specification: 60mm

• Radius specification: R=0.2±0.05

• Calibration force: 20 N applied along the axis of the rigid steel wire

• Force requirement: Minimum 20 N must be maintained during testing

• Reference planes: A-A’ and B-B’ (for calibration alignment)

Test Procedures:

• First, perform normal operation testing on the socket under test in accordance with relevant standard requirements to simulate real-world usage conditions.

• Calibrate the gauge: Apply a 20 N force along the axis of the rigid steel wire to ensure the A-A’ plane aligns practically with the B-B’ plane, confirming the inner spring’s characteristic meets specifications.

• Prepare the post-operation socket, ensuring it is in a stable state without obvious damage or deformation.

• Position the calibrated gauge correctly relative to the socket’s shutters as per standard guidelines.

• Apply a force of at least 20 N to the gauge during the test, adhering to the force requirement.

• Attempt to access the socket’s live parts through the shutters using the gauge.

• Record the test result; the socket passes if no access to live parts is achieved.

Applications:

• Post-operation safety verification of fixed household sockets to ensure shutter effectiveness.

• Compliance testing for sockets used in commercial, office, or public facility settings after prolonged use.

• Quality control and batch inspection in socket manufacturing plants to validate long-term protective performance.

• Conformity assessment by certification bodies and third-party testing laboratories for standard compliance.

• R&D and design optimization for socket manufacturers, testing shutter durability and protective reliability after normal operation.

• Safety audits and maintenance checks for electrical systems in residential buildings, hotels, and industrial workshops.

DIN-VDE 0620-1-Lehre 15 Prüfung der Nichtberührbarkeit von aktiven Teilen durch die Shutter hindurch nach der Prüfung des bestimmungsgemäßen Betriebs