Product No: SMT-PA135A

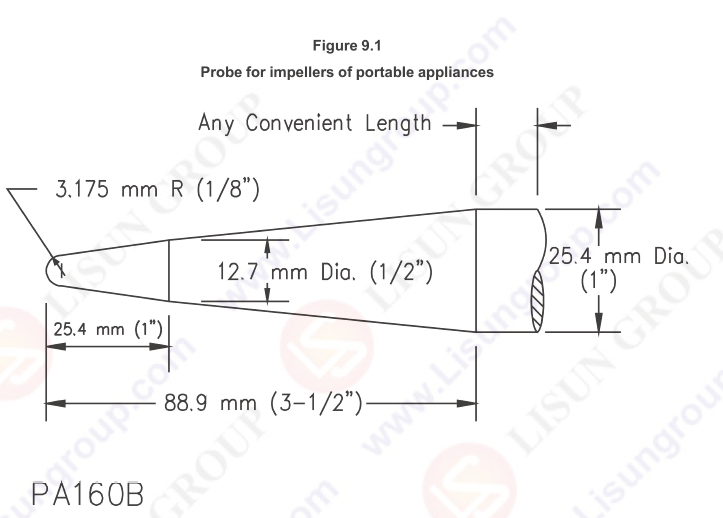

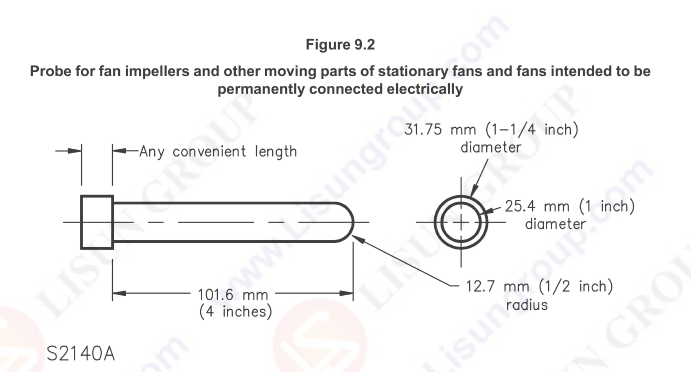

The UL 507 PA135A Probe is a specialized safety tool designed to test the insulation integrity of film-coated wires. The probes referenced in Table 9.1 and illustrated in Figures 9.1 and 9.2 shall be used as measuring instruments to judge the accessibility to uninsulated live parts and film-coated wire provided by openings and not as instruments to judge the strength of a material. Force is not to be applied to the probe when judging accessibility.

Specifications:

Probe Type: UL 507 PA135A Probe (for film-coated wire insulation integrity testing in fans/blowers)

Handle Material: Nylon (fully insulating, heat-resistant up to 100°C; non-slip grip for precise pressure control)

Key Dimensions:

– Head Length: 12.7mm(1/2 inch)

– Total Length: 101.6mm(4 inch)

– The Head Radius: 14.3mm(9/16 inch)

– Former Head Diameter: R4.8mm(3/16inch)

– The Tail Diameter: 19.1mm(3/4 inch)

Test Procedures:

1. Inspect the probe (no bent tip, cracked handle, or poor conductivity) and connect it to a leakage detection instrument.

2. Prepare the film-coated wire (from fan/blower) – clean, dry, and secure on a non-conductive surface.

3. Hold the insulating handle and align the brass tip with the wire’s film coating.

4. Glide the probe lightly along the wire’s entire length, maintaining consistent contact.

5. Monitor the detection instrument for signals (indicating coating defects and electric leakage).

6. Record defective sections and confirm if the wire meets safety requirements (pass/fail).

Applications:

1. Safety testing of film-coated wires in household pedestal fans and table fans (per UL 507:2023 Figure 8.6).

2. Verification of film-insulated wires in ceiling fans and exhaust fans (kitchen/bathroom) for U.S. markets.

3. Post-production audits of commercial air circulator wires to ensure insulation integrity per UL 507 standards.

UL 507 UL Probe for Film-coated Wire

UL 507 UL Probe for Film-coated Wire

Tags:SMT-PA135A , UL 1026 , UL 1278 , UL 507