Product No: SMT-PA160

The UL 1278 Figure 9.1 PA160 Hazardous Moving Parts Probe is a specialized safety tool designed for portable electric tools—such as drills, grinders, and sanders. It’s engineered to verify if hazardous moving components (e.g., gear trains, blade shafts, or motor rotors) remain inaccessible through tool guards or enclosure gaps. Featuring a rigid stainless steel probe tip (narrow enough for tight tool crevices) and an insulating nylon handle (for tester safety), to mimic accidental user contact.

Specifications:

Probe Type: UL 1278 Figure 9.1 PA160 Hazardous Moving Parts Probe (for portable electric tools)

Probe Material: Stainless steel (rigid, corrosion-resistant; withstands minor contact with moving parts)

Handle Material: Nylon (fully insulating, heat-resistant up to 100°C; non-slip grip for controlled operation in tight tool spaces)

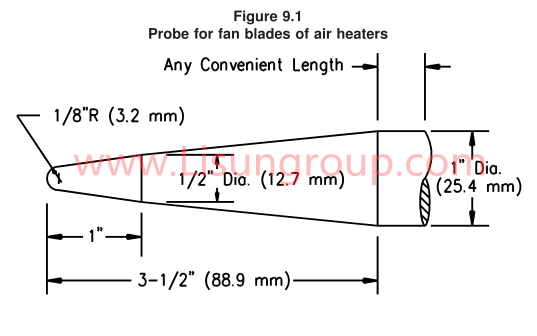

Key Dimensions:

– Total Length:88.9 mm(3.5 inch)

– Head Length:25.4 mm(1 inch)

– Head Radius: R3.2 mm(1/8 inch)

– Former Head Diameter:12.7 mm(1/2 inch)

– Tail Diameter:25.4 mm(1 inch)

Test Procedures:

1. Inspect the probe for damage (e.g., bent tip, cracked handle) to ensure structural integrity.

2. Power on the portable electric tool and activate its moving components (e.g., drill chuck, grinder wheel).

3. Hold the insulating handle and align the probe tip with gaps in tool guards or enclosures.

4. Apply steady 10N thrust to the probe—stop immediately if resistance from moving parts is felt.

5. Check if the probe touches rotating components or bypasses safety guards.

6. Record whether the tool meets safety requirements (pass/fail) and power off.

Applications:

1. Safety testing of hand-held electric drills (chuck gears and motor shafts) per UL 1278 Figure 8.3.

2. Verification of orbital sanders (pad drive mechanisms) to block access to moving parts for U.S. markets.

3. Quality control for electric screwdrivers (gear trains) during manufacturing.

4. Post-production audits of jigsaws (blade shafts and linkage parts) to meet UL 1278 safety standards.

Hazardous Moving Parts Probe PA160 UL of UL1278