Product No: GNGPL-3601

The BS 1363-2 Figure 1 Test Pin is a precision tool designed to verify that 13A socket-outlets (switched or unswitched) prevent accidental contact with live parts—critical for user safety during plug insertion/withdrawal. It features a steel probe with a spherical tip (for accurate gap navigation) and an insulated handle (to protect operators). Built to meet strict dimensional gauging requirements of BS 1363-2, it checks if live components are accessible when sockets are mounted/wired normally. Used in manufacturing and quality checks, it ensures 13A sockets comply with UK and global safety standards, reducing electric shock risks.

Specifications:

Tool Type: Test Pin (BS 1363-2 Figure 1; for verifying live part accessibility in 13A socket-outlets)

Probe Material: Steel (corrosion-resistant; spherical tip (SR) for smooth insertion; rigid to maintain dimensional accuracy)

Handle Material: Insulating plastic (resistance ≥ 100MΩ; heat-resistant up to 110°C; ergonomic grip for precision)

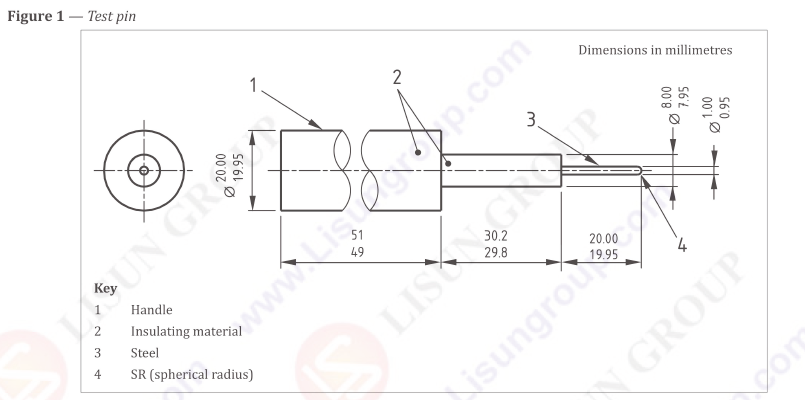

Key Dimensions (mm):

– Length Segments: 20.00-19.95mm, 29.8–30.2mm, 49–51mm

– Total Probe Length: Aligned with BS 1363-2 gauging requirements

– Tolerances: ±0.05mm for linear dimensions ≤25mm; ±0.2mm for over 25mm

Core Function: Checks if 13A sockets block access to live parts; validates dimensional compliance with BS 1363-2; ensures user safety during plug use

Compatibility: Designed for 13A switched/unswitched socket-outlets (household, commercial, and industrial types)

Test Procedures:

1. Inspect the test pin for bent tips, cracked insulation, or dimensional damage; confirm tip sphericity.

2. Mount and wire the 13A socket-under-test (EUT) exactly as it would be in normal use.

3. Hold the insulated handle, insert the steel probe into all EUT openings (socket slots, gaps).

4. Move the probe gently to explore potential contact with internal live parts.

5. Check if the probe touches any live components (use a live-part detector if needed).

6. Record results: Pass if no live-part contact; Fail if the probe reaches dangerous components.

Applications:

1. Testing household 13A wall sockets (per BS 1363-2:2016 Figure 1) to prevent electric shock during plug insertion.

2. Verifying commercial 13A power strips to ensure live parts stay inaccessible when plugs are withdrawn.

3. Quality control for 13A socket adaptors during manufacturing, meeting BS 1363-2 dimensional requirements.

4. Lab testing of industrial 13A unswitched sockets (per IEC 60884-1:2023) to validate global safety compliance.

5. Post-installation checks of 13A sockets in offices/retail spaces to confirm safe live-part isolation.

Test pin with BS 1363 Figure 1