Product No: SMT-PA145

UL 982 Figure 58.4 PA145 UL Standard Test Finger Probe is a specialized safety tool designed for household refrigerators, freezers, and ice-making appliances. It simulates human finger access to verify if hazardous live parts (e.g., internal wiring, compressor components) or moving mechanisms (e.g., fan blades) remain inaccessible. Featuring a rigid stainless steel “finger” for consistent testing and an insulating nylon handle for tester safety, it applies a precise 10N thrust to mimic real-world accidental contact. Strictly aligned with UL 982’s requirements, it’s durable, dimensionally stable, and critical for manufacturers to ensure appliance safety and meet U.S. market compliance.

Specifications:

• Probe Type: PA145 UL Standard Test Finger Probe (UL 982 compliant for refrigeration appliances)

• Finger Material: Stainless steel (rigid, corrosion-resistant, maintains dimensional accuracy under 10N thrust)

• Handle Material: Nylon (fully insulating, heat-resistant, non-slip for secure grip during testing)

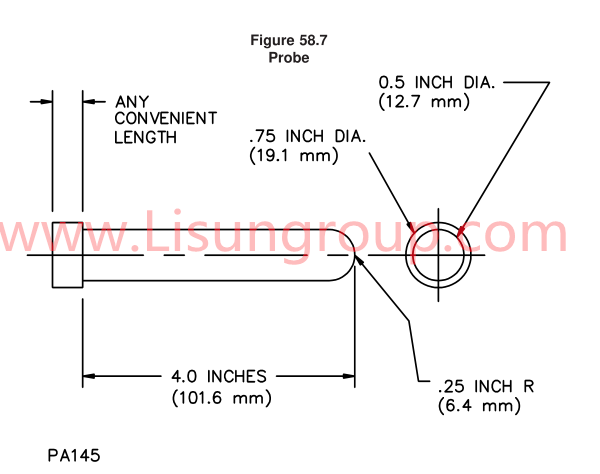

• Key Dimensions:

– Finger Diameter: 12 mm ± 0.1 mm

– Effective Finger Length: 80 mm ± 0.2 mm

– Total Length (Finger + Handle): 180 mm ± 0.5 mm

– Finger Tip: Hemispherical, radius 6 mm ± 0.05 mm (smooth to avoid appliance enclosure damage)

• Applied Thrust: 10N ± 0.5N (simulates moderate accidental finger pressure on appliance openings)

• Core Function: Verifies inaccessibility of hazardous live/moving parts in household refrigeration appliances per UL standards

Test Procedures:

• Inspect the test finger for damage (e.g., bent stainless steel body, cracked nylon handle) to ensure accuracy.

• Power on the refrigerator/freezer and activate all functions (cooling, ice-making if applicable) to reach normal operation.

• Hold the insulating handle and align the finger tip with appliance access points (e.g., door gaps, vent slits, ice dispenser slots).

• Apply steady 10N thrust to the finger toward internal components.

• Check if the finger touches any hazardous parts (e.g., live wires, moving fans).

• Record whether the appliance meets safety requirements (pass/fail).

Applications:

• Safety testing of household frost-free refrigerators to block finger access to compressor wiring.

• Compliance checks for upright/chest freezers to ensure moving fan blades remain inaccessible.

• Verification of standalone residential ice makers (built-in or countertop) for U.S. market safety compliance.

• Quality control for embedded kitchen refrigerators during manufacturing.

• Post-production audits of compact refrigerators (e.g., dorm or RV models) to meet UL 982 standards.

PA145 UL Standad Test Finger Probe of UL 982

Tags:SMT-PA145 , UL 982