Product No: SMT-PA215A

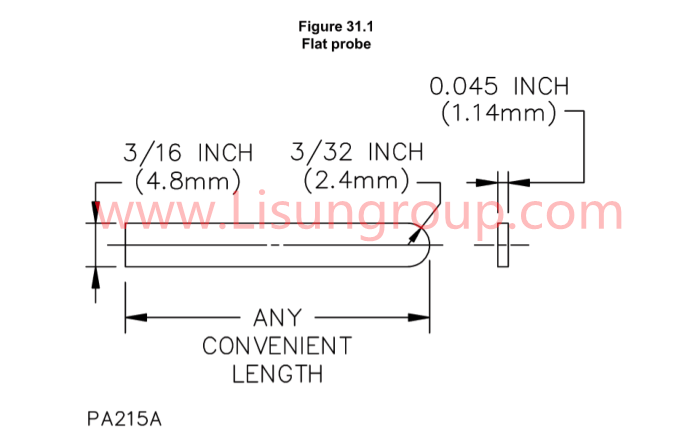

The Flat Probe PA215A (UL 498 Figure 31.1) is a specialized testing gauge designed to verify if plugs, sockets, and power connectors meet the structural and dimensional requirements of UL 498. Crafted from high-hardness material (over 50HRC) with a low thermal expansion coefficient, it maintains stable dimensions and tolerances even in varying environments—critical for consistent accuracy. Its precision-engineered flat design (with key dimensions like 0.045 inch, 3/16 inch, and 3/32 inch) fits into plug/socket slots to check compliance. Used across electronics, appliance, and connector industries, it ensures products meet global safety standards for reliable, hazard-free use.

Specifications:

Tool Type: UL 498 Figure 31.1 Flat Probe

Material: High-hardness alloy steel (hardness ≥ 50HRC; corrosion-resistant; low thermal expansion coefficient for dimension stability)

Key Dimensions:

– Thickness: 0.045 inch (1.14mm) ± 0.001 inch

– Width (1): 3/16 inch (4.8mm) ± 0.002 inch

– Width (2): 3/32 inch (2.4mm) ± 0.002 inch

– Working Length: Customizable (any convenient length for testing; typical 100–150mm)

– Total Length: Dependent on working length (standard 150–200mm)

Surface Finish: Smooth (surface roughness ≤ Ra 0.8μm; no burrs to avoid damaging test samples)

Thermal Stability: Low thermal expansion coefficient (≤ 12×10⁻⁶/°C; maintains tolerance accuracy between -10°C and 60°C)

Core Function: Verifies plug/socket structural compliance; checks dimensional accuracy against UL 498; ensures connector safety and compatibility

Test Procedures:

1. Inspect the probe for scratches, bends, or surface damage; confirm dimensions with a calibrated tool if needed.

2. Prepare the plug/socket under test (EUT) – clean it to remove dust or debris that could affect results.

3. Hold the probe by its non-test end, align its flat tip with the EUT’s slot (e.g., plug prong slot, socket opening).

4. Gently insert the probe into the slot – check if it fits smoothly without excessive force (indicates dimensional compliance).

5. Verify key dimensions: Ensure the probe’s thickness/width matches the EUT’s required slot size per UL 498.

6. Record results: Pass if probe fits correctly and dimensions align; Fail if fit is too tight/loose or dimensions deviate.

Applications:

1. Testing dimensional compliance of household power plugs (per UL 498:2023 Figure 31.1) to ensure compatibility with standard sockets.

2. Verifying slot accuracy in industrial power receptacles (compliant with CSA C22.2 No. 498:2023) for safe, secure connections.

3. Checking USB charger plug prongs (per IEC 60884-1:2023) to confirm structural fit in compatible sockets.

4. Quality control for extension cord socket slots during manufacturing, ensuring UL 498 compliance.

5. Post-production testing of smart home device power connectors to validate structural safety and compatibility.

Flat Probe PA215A with UL 498 Figure 31.1

Tags:SMT-PA215A