Product No: LS-B60

The LS-B60 Circuit Breaker Tripping Characteristic Testing System is a professional device specifically designed for circuit breaker performance testing. It employs PLC intelligent integrated control and a human-machine interface, providing a convenient and efficient operating experience for testing. The equipment organically combines a test box and a testing machine, with built-in specific test stations. Through scientific wiring methods, it meets the testing requirements of circuit breakers of different specifications. Simultaneously, it can precisely control the ambient temperature, ensuring that the testing process is conducted in a stable and safe environment. This system can complete performance tests related to circuit breaker delayed tripping and instantaneous tripping, as well as temperature rise tests. By automatically adjusting key test parameters such as output current, it accurately captures the performance of the circuit breaker under different operating conditions, comprehensively verifying whether the circuit breaker meets relevant usage requirements, and providing reliable testing support for circuit breaker quality control.

Standards:

| Standards No. | Standards Name |

| IEC 60947-1:2020 | Low-voltage switchgear and controlgear – Part 1: General rules |

| IEC 60947-2:2020 | Low-voltage switchgear and controlgear – Part 2: Circuit-breakers |

| IEC 60898-1:2020 | Moulded case circuit-breakers for household and similar installations – Part 1: Circuit-breakers for a.c. |

| IEC 60009-1:2019 | Rotating electrical machines – Part 1: Rating and performance |

| GB 14048.1-2020 | 低压开关设备和控制设备 第 1 部分:总则 |

| GB 14048.2-2020 | 低压开关设备和控制设备 第 2 部分:断路器 |

| GB 10963.1-2020 | 家用及类似场所用过电流保护断路器 第 1 部分:交流断路器 |

| GB 16917.1-2014 | 家用和类似用途的带过电流保护的剩余电流动作断路器 (RCBO) 第 1 部分:一般规则 |

Specification:

| Electrical Control Method | PLC intelligent integrated control, human-machine touch interface operation |

| Test Chamber | The test chamber is combined with the test machine, with a built-in delay position and an instantaneous position, and is arranged on the back panel in a terminal manner to meet the 1-4P circuit breaker test. When the temperature inside the chamber is too low, it can be heated, ranging from room temperature to 50 degrees, with a temperature resolution of 0.1 degrees and a temperature stability of ±1 degree, providing a reliable and safe environment for circuit breaker testing. |

| Test Items | • Small/molded case time-delay tripping characteristics: 1.13 times, 1.45 times, 2.55 times the current • Instantaneous tripping characteristics: 3~10 times the current • Temperature rise test |

| Time-delay Tripping Test | |

| Output Current | AC10~350A |

| Output Voltage | 0~5V |

| Output Current Path | 1-way output, multi-P circuit breaker contacts are tested by connecting several switches in series |

| Test Sample Range | 3~125A |

| Current Output Waveform | Sine wave (correction equipment current waveform distortion is no more than 5%, system error is no more than 3%) |

| Current Control Method | Automatic adjustment, current setting on touch screen |

| Current Accuracy | Class 0.5 |

| Voltage Accuracy | Class 0.5 |

| Transformer Ratio | 400/5A |

| Testing Time | 1~9999H 59M 59s |

| Testing Process | After applying 1.13 times the current, it will automatically rise to 1.45 times the current in 5 seconds |

| Fixture | Adopting terminal mode, one delay position, one instantaneous position; meeting 1-4P circuit breaker |

| Instantaneous Tripping Test | |

| Output Current | AC100~1500A |

| Output Voltage Number | 1 |

| Current Accuracy | 0.5 Class |

| Resolution | 1A |

| Instantaneous Test Time | ≤0.2s |

| Action Time Upper Limit Setting | 1~200ms |

| Action Time Lower Limit Setting | 1~200ms |

| Test Station | 1 |

| Timekeeping | 1~9999ms |

| Protection Function | Short circuit protection, overload protection, leakage protection |

| Temperature Rise Test | |

| Purpose of the Test | When the circuit breaker is tested under normal working conditions and specified conditions, the temperature rise of its components shall not exceed the limit values specified in Table 6, and the circuit breaker shall not be damaged to affect its function or safety of use. |

| Test Current | AC10-350A |

| Temperature Measurement Channel | 12 channels, temperature resolution 0.1 degrees |

| Accuracy | 0.2 Class |

| Measurement and Control Speed | 0.1 seconds per channel |

| Temperature Measurement Range | 0~200℃ |

| Thermocouple Model | T type |

• Quality inspection at the factory gate of miniature circuit breaker manufacturers;

• Performance verification testing during the R&D process of molded case circuit breakers;

• Third-party testing of circuit breaker tripping characteristics by electrical equipment testing institutions;

• Performance evaluation testing before circuit breaker selection in the power engineering field;

• Regular maintenance and performance spot checks by circuit breaker users.

IEC 60947-1 Clause 7.2.1 and 7.2.2

IEC 60947-2 Clause 4.7

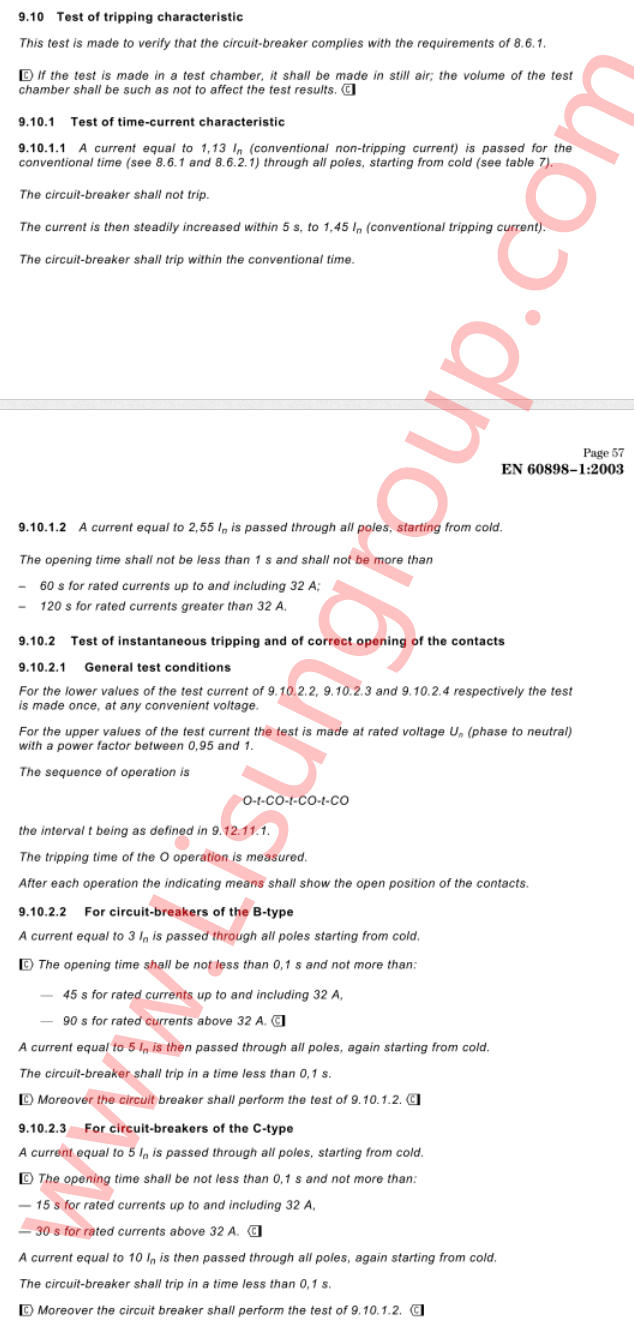

IEC 60898-1 Clause 9.10