Product No: GNGPL-3616

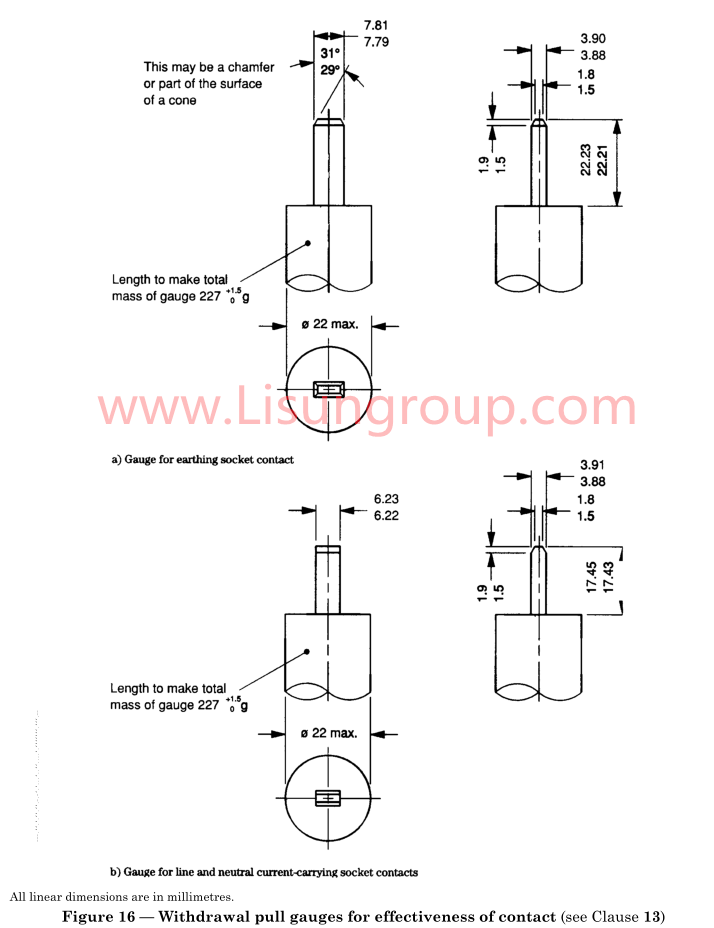

BS1363-2 Figure 16 Withdrawal Pull Gauges for Effectiveness of Contact is a specialized testing tool designed to verify the contact effectiveness, structural compliance, and dimensional accuracy of plugs and sockets in line with BS 1363 standards, as detailed in Figure 16 of BS 1363-2 (“13 A plugs, socket-outlets, adaptors and connection units – 13 A switched and unswitched socket-outlets. Specification”). It consists of two dedicated gauge variants for targeted inspections, adhering strictly to the standard’s requirements for dimensions, tolerances, material properties, hardness, and surface roughness. With a material hardness exceeding 50HRC and a low thermal expansion coefficient, the gauge ensures stable and reliable performance, delivering precise results for contact effectiveness assessments through simulated insertion and prescribed force application.

Specifications

• Compliance standard: BS 1363-2 (“13 A plugs, socket-outlets, adaptors and connection units – 13 A switched and unswitched socket-outlets. Specification”) Figure 16 Gauge variants: a) For earthing socket contact; b) For line and neutral current-carrying socket contacts

• Material hardness: Over 50HRC

• Material thermal expansion coefficient: Low

• All linear dimensions: Specified in millimetres

• Total mass requirement: 227 ±3g per gauge variant

• Maximum σ value: 22 (for both gauge variants)

• Key attributes (dimensions, tolerances, material, surface roughness): Fully compliant with BS 1363 standard requirements

• Dimensional stability: Stable and reliable due to low thermal expansion coefficient

• Design features: May include chamfers or conical surface sections as specified in the standard

Test Procedures

• Prepare the socket sample for testing, ensuring it is free from damage, debris, or wear that could impact contact effectiveness or test accuracy.

• Select the appropriate gauge variant (earthing socket contact gauge or line/neutral current-carrying socket contact gauge) based on the test objective.

• Inspect the selected gauge to confirm its surface is clean, free from deformation or wear, and that its dimensions and mass (227 ±3g) meet BS 1363-2 Figure 16 requirements.

• Simulate the insertion process by inserting the gauge into the corresponding contact slot of the socket sample (earthing slot for variant a, line/neutral slots for variant b) in accordance with Clause 13 of the standard.

• Apply the prescribed vertical downward force (poise) as specified by the BS 1363 standard to assess the socket’s contact retention and structural integrity.

• Verify whether the socket maintains compliance with standard requirements during and after force application, checking for proper fit and contact effectiveness.

• Repeat the process with the other gauge variant if testing both earthing and line/neutral contacts.

• Document the test results comprehensively, indicating whether the socket sample meets BS 1363 standards based on the gauge’s inspection outcomes.

Applications

• Contact effectiveness testing of sockets to verify compliance with BS 1363-2 Figure 16 requirements, including earthing and line/neutral current-carrying contacts.

• Dimensional and structural conformity inspection of plugs and sockets in the electronics industry.

• Quality control and compliance verification in the electrical appliance industry to ensure the safety and reliability of 13 A plug-and-socket assemblies.

• R&D and production quality assurance for manufacturers of 13 A plugs, socket-outlets, adaptors, and related connection units.

• Conformity assessment for electrical connection product manufacturers requiring adherence to BS 1363 standards.

• Routine inspection and performance validation of socket contacts in industries relying on standardized plug-and-socket systems.

Withdrawal Pull Gauges for Effectiveness of Contact of BS1363-2 Figure 16