Product No: GNGPL-3615

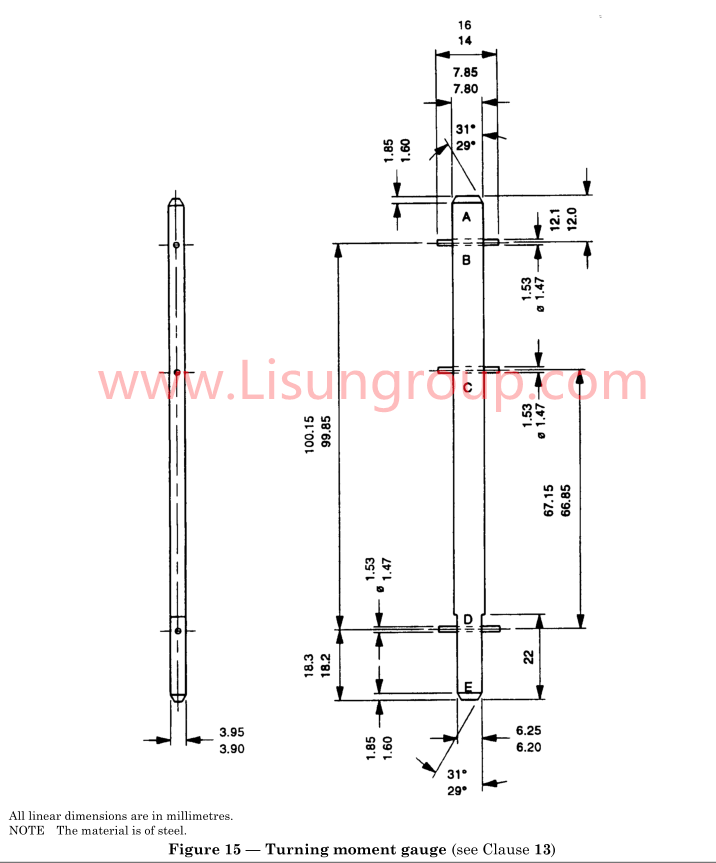

Turning Moment Gauge Required by BS 1363-2 Figure 15 is meticulously designed to validate the structural and dimensional compliance of plugs and sockets with the BS 1363 standard, as specified in Figure 15 of BS 1363-2 (“13 A plugs, socket-outlets, adaptors and connection units – 13 A switched and unswitched socket-outlets. Specification”). It adheres strictly to the standard’s requirements for dimensions, tolerances, material, hardness, and surface roughness, featuring a steel construction with a hardness exceeding 50HRC and a low thermal expansion coefficient. These characteristics ensure exceptional dimensional stability and reliability, enabling accurate and consistent turning moment-related inspections for quality assurance in relevant applications.

Specifications

• Compliance standard: BS 1363-2 (“13 A plugs, socket-outlets, adaptors and connection units – 13 A switched and unswitched socket-outlets. Specification”) Figure 15

• Material: Steel

• Material hardness: Over 50HRC

• Material thermal expansion coefficient: Low

• All linear dimensions: Specified in millimetres

• Key attributes (dimensions, tolerances, surface roughness): Fully compliant with BS 1363 standard requirements

• Dimensional stability: Stable and reliable due to low thermal expansion coefficient

Test Procedures

• Prepare the plug or socket sample for testing, ensuring it is free from damage, corrosion, or debris that could affect test accuracy.

• Inspect the test gauge to confirm its steel structure is intact, surface is clean, free from wear or deformation, and all specifications meet BS 1363-2 Figure 15 requirements.

• Mount the sample securely in a suitable fixture to ensure stability during the turning moment inspection, following the guidelines in Clause 13 of the BS 1363-2 standard.

• Align the gauge with the sample’s relevant structural features, ensuring precise positioning for turning moment-related dimensional and structural verification.

• Conduct the inspection to assess the sample’s turning moment-related dimensions and structural conformity, cross-checking against the gauge’s calibrated parameters.

• Verify that the sample’s key dimensions and structural attributes adhere to the tolerance limits specified in the standard.

• Document the test results in detail, indicating whether the sample complies with the BS 1363 standard based on the gauge’s inspection findings.

Applications

• Dimensional and structural compliance testing of plugs and sockets against BS 1363-2 Figure 15 requirements, with a focus on turning moment-related attributes.

• Quality control and inspection processes in the electronics industry for plug-and-socket components.

• Compliance verification in the electrical appliance industry to ensure the safety, compatibility, and performance of 13 A plug-and-socket assemblies.

• R&D and production quality assurance for manufacturers of 13 A plugs, socket-outlets, adaptors, and related connection units.

• Conformity assessment in industries producing electrical connection products that require adherence to BS 1363-2 standards.

Turning Moment Gauge of BS 1363-2 Figure 15