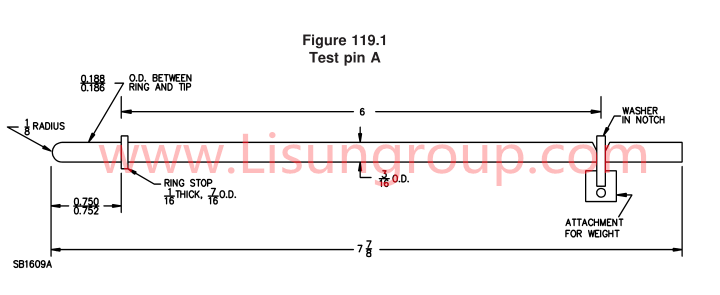

Product No: GNGPL-SB1609A

UL 498 Figure 119.1 SB1609A Test Pin A is a specialized and high-precision testing component engineered to comply with the requirements of UL 498 Figure 119.1, serving as a critical tool for verifying the dimensional accuracy and contact performance of electrical receptacles and related connection devices. Crafted from premium, wear-resistant materials with strict dimensional control, it ensures consistent and reliable testing outcomes, helping manufacturers and testing institutions confirm that their products meet the safety and compatibility standards set forth in UL 498. Its precise design and stable mechanical properties make it an indispensable instrument for quality assurance in the electrical connection component industry.

Specifications

• Made of high-hardness alloy material with hardness rating of ≥58 HRC for enhanced durability and wear resistance

• Dimensional tolerances are fully aligned with the requirements specified in UL 498 Figure 119.1

• Surface is treated with anti-corrosion and anti-wear coating to maintain long-term dimensional stability

• Key dimensional parameters include pin diameter and length that strictly match the standard’s defined values with minimal deviation

• Compatible with standard testing platforms and can be integrated into automated or manual testing setups

• Operating temperature range covers -20℃ to 60℃ to adapt to various testing environment conditions

Test Procedures

• Prepare the test pin and the receptacle to be tested, ensuring both are free of dust, debris, or any contaminants that may impact testing accuracy.

• Secure the receptacle in a fixed and stable position on the testing platform to prevent displacement during the test process.

• Align the test pin with the contact slot of the receptacle at a vertical angle as specified in UL 498 Figure 119.1, avoiding any tilting that could cause measurement errors.

• Insert the test pin into the receptacle’s contact terminal at a steady and controlled speed, and measure the insertion force and retention force using dedicated force-testing equipment if required.

• Verify whether the test pin can fit into the receptacle smoothly within the standard-specified range and check for proper contact between the pin and the receptacle’s internal terminals.

• Remove the test pin from the receptacle and inspect both the pin and the receptacle for any deformation or damage; record all test data and judge whether the receptacle meets UL 498 compliance criteria based on the results.

Applications

• Dimensional and contact performance testing of household electrical receptacles in manufacturing facilities to ensure batch product quality

• Compliance verification of industrial-grade power sockets by third-party certification and testing organizations for UL certification applications

• R&D phase validation of new receptacle designs, helping engineers optimize product structure to meet UL 498 safety standards

• Incoming quality inspection of receptacle components by electrical appliance assembly enterprises to avoid non-compliant parts entering the production chain

• Periodic quality audits of in-service receptacles in electrical safety inspection projects to assess their continued compliance with safety standards

UL 498 Figure 119.1 SB1609A Test Pin A