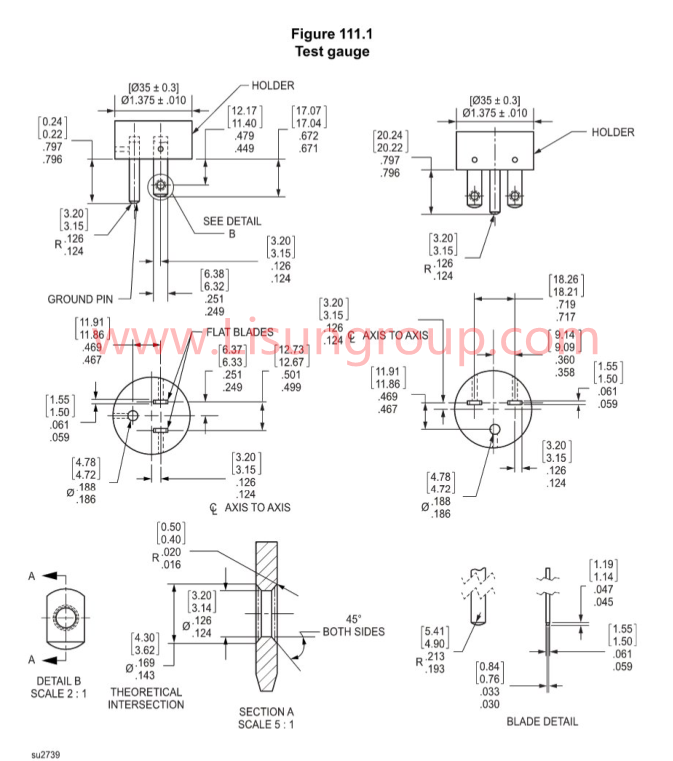

Product No: GNGPL-SU2739

This Test Gauge of UL 498 Figure 111.1 is precision-manufactured to verify the structural and dimensional compliance of plugs and sockets with UL 498 standards, specifically adhering to the requirements of Figure 111.1. It features tool steel construction with high hardness, strict adherence to standard-specified dimensions and tolerances, minimal thermal expansion, and optimized surface finish, ensuring stable performance and accurate results for electrical component inspection.

Specifications:

• Applicable standard: UL 498 Figure 111.1

• Material: Tool steel (pins and blades)

• Rockwell hardness: C58 to C60

• Key dimensional parameters (inches/mm):

– Ground pin diameter: 0.251 in [6.38 mm] / 0.249 in [6.32 mm]

– Flat blade thickness: 0.126 in [3.20 mm] / 0.124 in [3.15 mm]

– Axis-to-axis distance (flat blades): 0.719 in / 0.717 in

– Overall length segment: 1.375 ± 0.010 in [35 ± 0.3 mm]

– Blade radius (sharp edge removal): 0.016–0.020 in [0.40–0.50 mm]

– Surface finish (blades): Maximum 32 microinch [813 nm] (90° to major axis)

– General tolerance (unspecified dimensions): ±0.012 in [±0.3 mm]

• Material thermal expansion coefficient: Small, ensuring dimensional stability

• Compatible configurations: 1-15R, 5-20R, 5-20RA, 6-20A, 6-20RA

Test Procedures:

• Inspect the test gauge for cleanliness, no visible damage, or dimensional irregularities before use; verify surface finish with 10X optical magnification if needed.

• Secure the plug or socket under test in a stable fixture, ensuring alignment with the gauge’s compatible configuration (1-15R, 5-20R, etc.).

• Align the gauge’s pins and blades with the corresponding slots/holes of the test sample as outlined in UL 498 Figure 111.1.

• Conduct structural and dimensional inspection by guiding the gauge into the product’s features, checking for proper fit and compliance with specified tolerances.

• Verify that all critical dimensions (e.g., pin/blade size, axis distance) of the product match UL 498 requirements.

• Document test results and confirm whether the product meets the standard’s compliance criteria.

Applications:

• Structural and dimensional inspection of plugs and sockets to ensure conformity with UL 498 standards.

• Quality control processes in electronics and electrical appliance manufacturing industries.

• Conformity testing for plug and socket products on production lines and in workshops.

• R&D testing for optimizing the design of plug and socket components (compatible with 1-15R, 5-20R, etc., configurations).

• Compliance verification in third-party testing laboratories and certification institutions.

SU2739 Test Gauge of UL498 Figure 111.1

Test Gauge with UL498 Figure 111.1