Product No: GNGPL-3611

Go Gauges for Socket-Outlet According to BS1363-1 Figure 11 is specifically designed for testing socket-outlets to ensure compliance with BS 1363-1 standards. It is used to verify critical parameters such as the relative position, size, and depth of the socket’s holes, as well as the fit of the socket’s joint surface, providing reliable and accurate assessment for manufacturers and quality control teams.

Specifications:

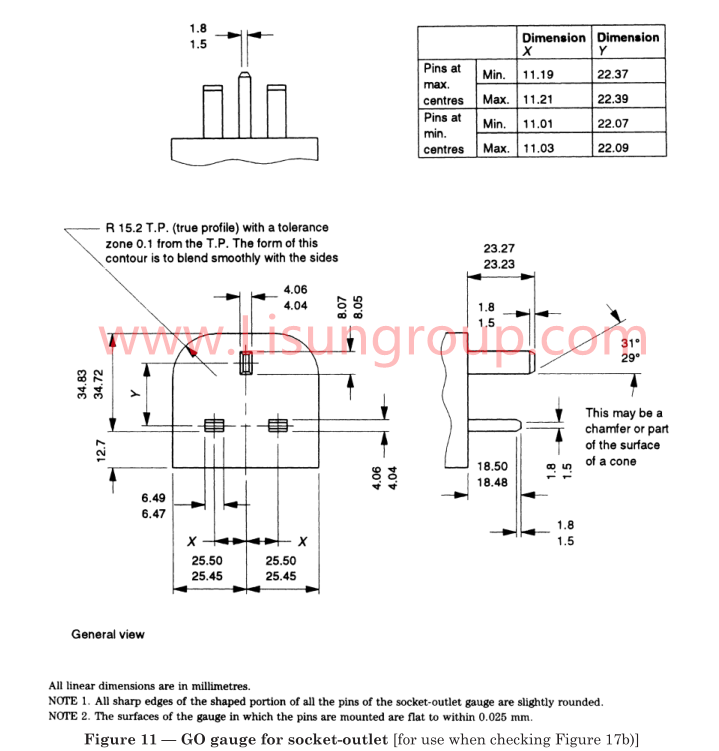

• Complies with BS 1363-1 “13 A plugs, socket-outlets, adaptors and connection units – Rewirable and non-rewirable 13 A fused plugs. Specification” Figure 11

• Available in two specifications: large and small

• Material hardness of over 50HRC

• Small thermal expansion coefficient for stable and reliable dimensions and tolerances

• All linear dimensions are in millimetres

• Slightly rounded sharp edges on the shaped portion of all pins

• Mounting surfaces of the pins are flat within 0.025 mm

• Contour features a true profile (R 152 T.P.) with a tolerance zone of 0.1 from the T.P., blending smoothly with the sides (may be a chamfer or part of a cone surface)

• Pin dimension ranges (at max. centres): Dimension * (11.19 – 11.21 mm), Dimension Y (22.37 – 22.39 mm)

• Pin dimension ranges (at min. centres): Dimension * (11.01 – 11.03 mm), Dimension Y (22.07 – 22.09 mm)

• Gauge dimensions, tolerances, material, and surface roughness meet standard requirements

Test Procedures:

• Prepare the socket test sample and ensure it is clean and free from damage or debris that may affect test results.

• Select the appropriate size (large or small) of the go gauge based on testing requirements.

• Align the gauge’s pins with the corresponding holes of the socket-outlet.

• Insert the gauge into the socket-outlet smoothly and check if the pins fit properly without excessive resistance.

• Verify the relative position of the socket’s holes by confirming the gauge’s alignment with the socket’s structure.

• Assess the size and depth of the socket’s holes to ensure they match the gauge’s specifications as per BS 1363-1.

• Check the fit of the socket’s joint surface with the gauge to confirm compliance with standard requirements.

• Record the test results, noting whether the socket-outlet meets all BS 1363-1 specifications based on the gauge’s performance.

Applications:

• Quality inspection of socket-outlets in the electronics industry to ensure product compliance.

• Testing of plug and socket products in the electrical appliance manufacturing sector.

• Compliance verification for manufacturers producing plugs, socket-outlets, and related electrical components.

• Quality control processes in industries involving the production and distribution of electrical connection devices.

• R&D testing for new socket-outlet designs to validate adherence to BS 1363-1 standards.

• Third-party testing and certification services for electrical products requiring BS 1363-1 compliance.

Go Gauges for Socket-Outlet of BS1363-1 Figure 11