Product No: GNGPL-5403

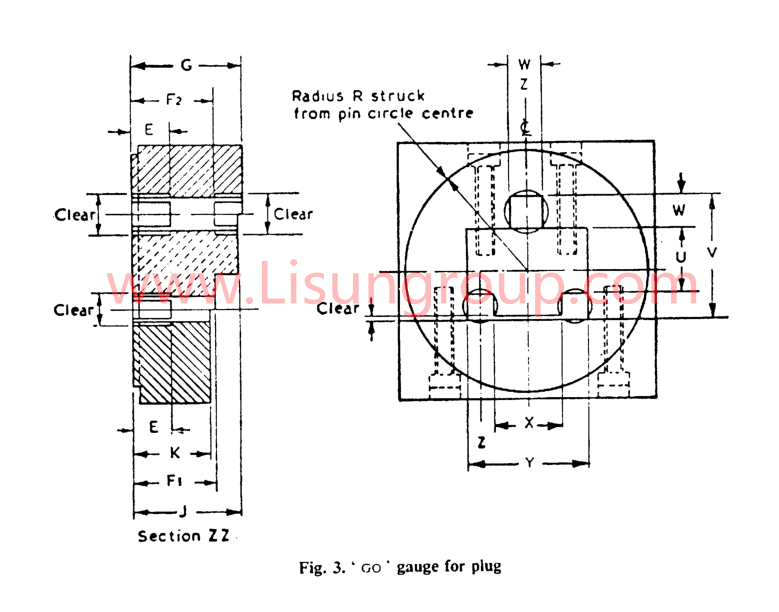

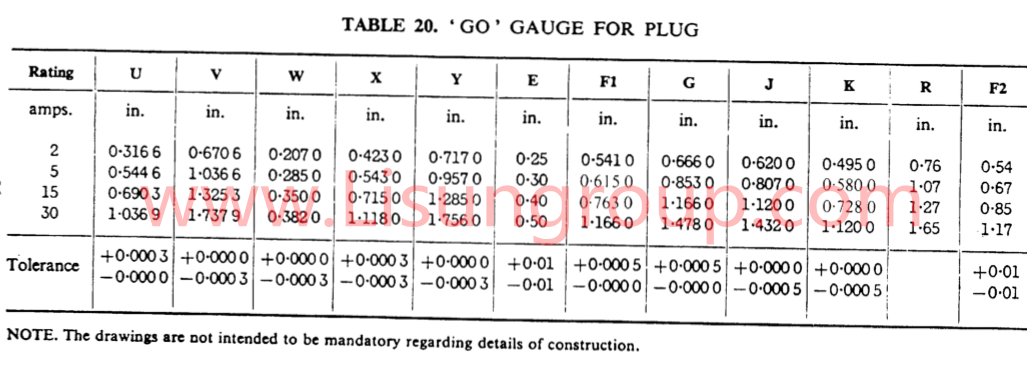

BS 546 Figure 3 Go Gauge for Plug is a precision-engineered testing instrument designed to verify the structural and dimensional compliance of plugs with BS 546 standards, as specified in Figure 3 of BS 546 (“Two-pole and earthing-pin plugs, socket-outlets and adaptors. Specification”). It adheres strictly to the standard’s requirements for dimensions, tolerances, material properties, hardness, and surface roughness, featuring a specialized design with key structural elements like a radius struck from the pin circle centre. With a material hardness exceeding 50HRC and a low thermal expansion coefficient, the gauge ensures exceptional dimensional stability and reliable performance, enabling accurate validation of whether plugs meet the “go” criteria for proper fit and conformity.

Specifications

• Compliance standard: BS 546 (“Two-pole and earthing-pin plugs, socket-outlets and adaptors. Specification”) Figure 3

• Gauge type: Go gauge (for plug dimensional and structural verification)

• Material hardness: Over 50HRC

• Material thermal expansion coefficient: Low

• All linear dimensions: Specified in accordance with BS 546 Figure 3 requirements

• Key design feature: E radius struck from the pin circle centre

• Key attributes (dimensions, tolerances, material, surface roughness): Fully compliant with BS 546 standard requirements

• Dimensional stability: Stable and reliable due to low thermal expansion coefficient

Test Procedures

• Prepare the plug sample for testing, ensuring it is free from damage, deformation, dirt, or debris that could affect test accuracy.

• Inspect the Go gauge to confirm its surface is clean, free from wear or misalignment, and all structural features (including the E radius) meet BS 546 Figure 3 specifications.

• Align the plug sample with the Go gauge, ensuring proper positioning of the plug’s pins and body relative to the gauge’s reference points.

• Attempt to fit the plug into the gauge smoothly, following the standard’s implied testing methodology for “go” gauges (i.e., verifying the plug can engage with the gauge without excessive force).

• Check for full and proper seating of the plug within the gauge, confirming that all critical dimensions of the plug align with the gauge’s calibrated parameters.

• Verify that there is no binding or resistance indicating dimensional non-compliance during the fitting process.

• Record the test results, noting whether the plug successfully meets the “go” criteria and complies with BS 546 standards based on the gauge’s inspection outcomes.

Applications

• Dimensional and structural compliance testing of plugs to verify adherence to BS 546 Figure 3 requirements.

• Quality control processes in the electronics industry for plug components.

• Compliance verification in the electrical appliance industry to ensure the safety and compatibility of plugs with BS 546-compliant socket-outlets and adaptors.

• R&D and production quality assurance for manufacturers of two-pole and earthing-pin plugs.

• Conformity assessment for electrical component manufacturers requiring adherence to BS 546 standards.

• Routine inspection of plugs in industries relying on BS 546-compliant electrical systems, such as commercial, industrial, or residential applications.

• Pre-shipment quality checks for plug manufacturers to ensure products meet market access requirements for BS 546 compliance.

Go Gauge for Plug of BS 546 Figure 3

Go Gauge for Plug of BS 546 Figure 3

Tags:BS 546 , GNGPL-5403