Product No: GNGPL-31G1

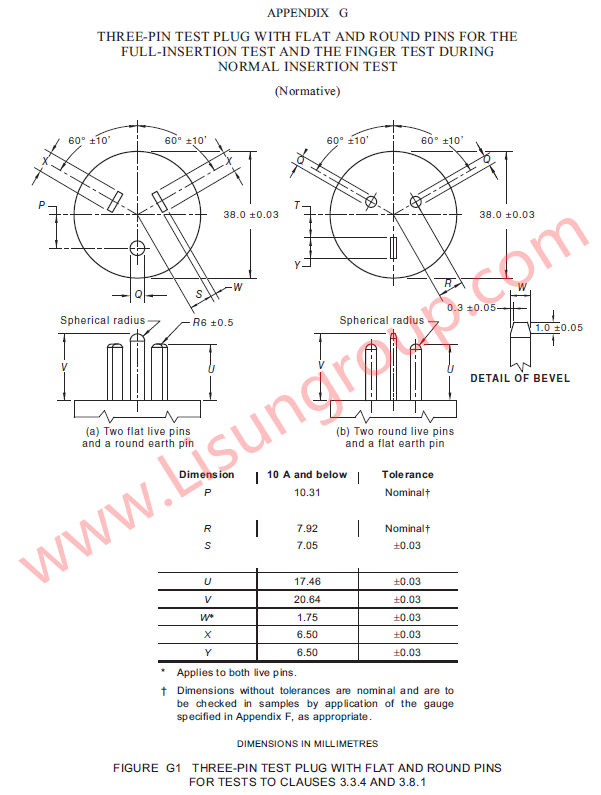

This AS/NZS 3112 Figure G1 Three-pin Test Plug with Flat and Round Pins for the Full-insertion Test and the Finger Test During Normal Insertion Test is precision-engineered in strict compliance with the specifications outlined in AS/NZS 3112:2017 Figure G1, a key normative standard for electrical plugs and sockets in Australia and New Zealand. It is specifically designed for two critical tests: the full-insertion test and the finger test during normal insertion, featuring both flat and round pins to simulate real-world usage scenarios. By verifying the proper insertion depth of plugs and the safety of socket openings (preventing finger access to live parts), this test plug ensures that electrical products meet the rigorous safety and performance requirements of AS/NZS 3112, safeguarding users against electric shock and other hazards.

Specifications:

• Fully conforms to AS/NZS 3112:2017 standard requirements, aligning with Figure G1 normative specifications

• Three-pin configuration with dual pin types: flat and round (covering variants: two flat live pins + one round earth pin; two round live pins + one flat earth pin)

• Key dimensional tolerance: Pin length 38.0±0.03 mm (for both flat and round pins)

• Angular tolerance for pin bevels: 60°±10′

• Spherical radius specifications: S R6±0.5 mm; additional spherical radius 0.3±0.05 mm

• Engineered with precise pin spacing and alignment to replicate standard plug dimensions

• Manufactured from high-quality, durable materials to maintain dimensional stability and repeatable test results

• Designed to facilitate both full-insertion verification and finger access prevention testing

Test Procedures:

• Inspect the test plug for any damage, deformation, or dimensional deviations, and confirm its pins, bevels, and radii comply with AS/NZS 3112:2017 Figure G1 specifications.

• Prepare the socket sample, ensuring it is clean, free from burrs, loose components, or structural defects that may affect test results.

• Secure the socket in a stable, vertical fixture to simulate real-world installation and ensure consistent positioning.

• Full-insertion test: Align the test plug (selecting the appropriate flat/round pin variant) with the socket’s openings and insert it fully with steady, controlled force.

• Verify that the plug achieves complete insertion as specified by AS/NZS 3112, ensuring no excessive resistance or incomplete seating.

• Finger test during normal insertion: While inserting the test plug into the socket (at the midpoint of the insertion process), use a standard test finger to check if it can access live parts through the socket openings.

• Confirm compliance: The test passes if full insertion is achieved and the test finger cannot reach live components during insertion.

• Remove the test plug slowly, inspecting both the plug and socket for any signs of wear or damage.

• Record test results, documenting insertion depth, finger access observations, and whether the sample meets AS/NZS 3112 requirements.

Applications:

• Quality control testing of sockets and plugs in manufacturing facilities to verify full-insertion and finger safety compliance with AS/NZS 3112.

• Compliance assessment by certification bodies and third-party testing laboratories for AS/NZS 3112 certification of electrical products.

• R&D testing for the design optimization of plugs and sockets, ensuring alignment with Australian and New Zealand safety standards.

• Routine inspection of production lines producing household, commercial, and industrial electrical sockets for the Australian and New Zealand markets.

• Dimensional and safety verification of socket components supplied by vendors to meet AS/NZS 3112:2017 requirements.

• Post-production quality audits to confirm the safety and performance of electrical products before market release in Australia and New Zealand.

• Safety validation for electrical equipment manufacturers integrating AS/NZS 3112-compliant plugs and sockets.

AS/NZS 3112 Figure G1 Three-pin Test Plug with Flat and Round Pins for the Full-insertion Test and the Finger Test During Normal Insertion Test