Product No: GNGPL-631C4ABCD

This NF C 61-314 Figure C4 Gauge to Check Extraction Force is precision-engineered in strict compliance with the specifications outlined in NF C 61-314 Figure C4, designed exclusively to verify the extraction force of minimum opening contact tubes for 6A/250V and 16A/250V household and similar electrical socket systems. It includes four dedicated gauge variants tailored to different device types, ensuring that the contact tubes maintain adequate retention force to prevent accidental disconnection—core to the standard’s requirement that the gauge must not fall from the cell (alvéole) within the first 30 seconds. By providing accurate and standardized extraction force testing, this tool safeguards the safety, reliability, and compliance of electrical products adhering to NF C 61-314 standards.

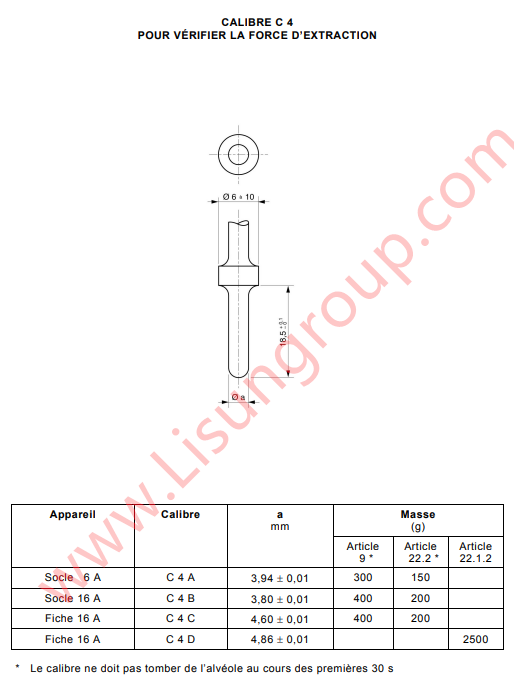

Specifications:

• Fully conforms to NF C 61-314 standard requirements, aligning with Figure C4 specifications for extraction force testing

• Comprehensive set including four gauge variants (C4A, C4B, C4C, C4D) for targeted applications

– Gauge C4A (for 6A sockets): Diameter (a) 3.94±0.01 mm, applicable weights 300g and 150g

– Gauge C4B (for 16A sockets): Diameter (a) 3.80±0.01 mm, applicable weights 400g and 200g

– Gauge C4C (for 16A plugs): Diameter (a) 4.60±0.01 mm, applicable weights 400g and 200g

– Gauge C4D (for 16A plugs): Diameter (a) 4.86±0.01 mm, applicable weight 2500g

• Manufactured from high-precision, durable materials to maintain dimensional stability and consistent test performance

• Engineered to fit minimum opening contact tubes without forced insertion, ensuring accurate extraction force measurement

• Complies with the core standard requirement: Gauge must not fall from the cell within 30 seconds

Test Procedures:

• Select the appropriate gauge variant (C4A/C4B/C4C/C4D) based on the test sample (6A/16A socket or 16A plug) and confirm its diameter and tolerance meet NF C 61-314 Figure C4 specifications.

• Prepare the contact tube sample (cell/alvéole), ensuring it is clean, free from burrs, deformation, or contamination that may affect retention force results.

• Secure the sample in a stable, vertical fixture to simulate real-world usage and ensure consistent positioning during testing.

• Insert the selected gauge into the contact tube cell with gentle, non-forced pressure until fully seated (per standard requirements).

• Attach the specified weight (matching the gauge variant) to the gauge, ensuring the weight is suspended vertically without additional tension or support.

• Start a 30-second timer immediately after attaching the weight and observe whether the gauge remains seated in the cell.

• Confirm compliance if the gauge does not fall from the cell within the 30-second period; note non-compliance if it dislodges before the timer ends.

• Remove the weight and gauge slowly, inspecting both the gauge and sample for any signs of damage or wear.

• Repeat the process for additional samples or alternate gauge variants as needed, documenting all test results (including pass/fail status and observations).

Applications:

• Quality control testing of contact tubes for 6A/16A sockets and 16A plugs in manufacturing facilities to verify extraction force compliance.

• Compliance assessment by certification bodies and third-party testing laboratories for NF C 61-314 certification of electrical products.

• R&D testing for the design optimization of contact tubes, ensuring adequate retention force to prevent accidental disconnection.

• Routine inspection of production lines producing household and similar electrical sockets, plugs, and contact components.

• Dimensional and performance verification of contact tube components supplied by third-party vendors to meet NF C 61-314 requirements.

• Post-production quality audits for electrical equipment (e.g., power sockets, plugs, connectors) relying on 6A/16A contact systems.

• Quality assurance for manufacturers exporting electrical products to markets requiring NF C 61-314 compliance (e.g., France and French-speaking regions).

NF C 61-314 Figure C4 Gauge to Check Extraction Force