Product No: GNGPL-631C2

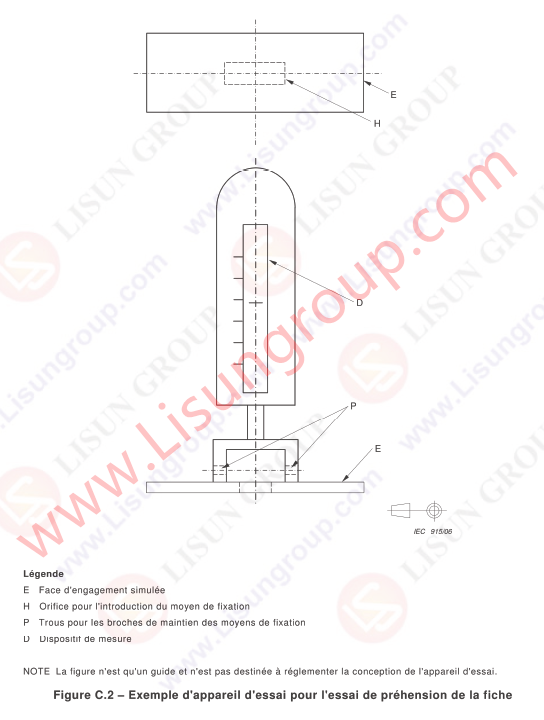

This NF C 61-314 Figure C.2 Gauge Apparatus for the Plug Grip Test is precision-engineered in strict compliance with the specifications outlined in NF C 61-314 Figure C.2, a key standard for household and similar electrical socket systems (6A/250V and 16A/250V). It is specifically designed to test the size of entry holes for plug pins, ensuring that the plug grip (prehension de la fiche) meets the standard’s dimensional and functional requirements. By simulating the engagement interface of plugs and sockets, this apparatus provides reliable verification of entry hole dimensions, safeguarding the compatibility, safety, and proper functionality of plugs and corresponding sockets adhering to NF C 61-314 standards.

Specifications:

• Fully conforms to NF C 61-314 standard requirements, aligning with Figure C.2 specifications for plug grip testing

• Designed to verify the size of plug pin entry holes, with targeted dimensions of 5.3mm and 5.8mm

• Features a simulated engagement face (Face d’engagement simulée) to replicate real-world plug-socket interaction

• Incorporates fixing means insertion holes (Orifice pour l’introduction du moyen de fixation) and retaining pin holes (Trous pour les broches de maintien) for secure apparatus setup

• Equipped with integrated measurement devices (Dispositif de mesure) for accurate dimensional verification

• Manufactured from high-precision, durable materials to ensure dimensional stability and repeatable test results

• Complies with the standard’s guideline that the apparatus design serves as a reference (not restrictive to test equipment design) while maintaining core functional requirements

Test Procedures:

• Inspect the gauge apparatus for any damage, deformation, or contamination, and confirm its key components (simulated engagement face, measurement devices) are in proper working condition.

• Prepare the test sample (socket or plug component with entry holes) and ensure it is clean, free from burrs, or structural defects that may affect test accuracy.

• Secure the gauge apparatus on a stable, flat surface using the designated fixing means, ensuring it is aligned to avoid measurement errors.

• Position the test sample onto the apparatus, aligning the plug pin entry holes with the apparatus’s simulated engagement face and measurement reference points.

• Use the integrated measurement device to verify the dimensions of the entry holes, focusing on the 5.3mm and 5.8mm target specifications outlined in NF C 61-314 Figure C.2.

• Check the fit between the sample’s entry holes and the apparatus’s engagement interface, ensuring compliance with the standard’s grip and dimensional requirements.

• Record the measured dimensions of the entry holes and compare them against the standard’s specified tolerances.

• Confirm compliance if the entry hole sizes fall within the acceptable range; document any deviations from the standard requirements.

• Remove the sample carefully, inspect both the sample and apparatus for wear, and reset the setup for subsequent tests to maintain consistency.

Applications:

• Quality control testing of sockets and plug components in manufacturing facilities to verify plug pin entry hole dimensions.

• Compliance assessment by certification bodies and third-party testing laboratories for NF C 61-314 certification of electrical products.

• R&D testing for the design optimization of plugs and sockets, ensuring entry hole dimensions meet grip and compatibility requirements.

• Routine inspection of production lines producing household and similar electrical sockets (6A/250V and 16A/250V) and corresponding plugs.

• Dimensional verification of socket entry holes supplied by third-party vendors to ensure conformance with NF C 61-314 standards.

• Post-production quality audits for electrical equipment (e.g., power sockets, plugs) to confirm proper plug grip functionality before market release.

• Quality assurance for manufacturers exporting electrical products to markets requiring NF C 61-314 compliance (e.g., France and French-speaking regions).

NF C 61-314 Figure C.2 Gauge Apparatus for the Plug Grip Test