Product No: GNGPL-631C1

This Gauge for NF C 61-314 Figure C.1- Reference Sheet for the Grip Test is precision-engineered in strict compliance with the specifications outlined in NF C 61-314 Figure C.1, a critical standard for 6A/250V and 16A/250V household and similar electrical socket systems. It serves as a specialized tool to verify the impossibility of single-pole insertion of plugs, a key safety requirement to prevent electric shock and other hazards. By providing a standardized reference for grip testing, the gauge ensures that plugs and corresponding sockets adhere to the dimensional and functional criteria of NF C 61-314, safeguarding the safety and reliability of electrical products in daily use.

Specifications:

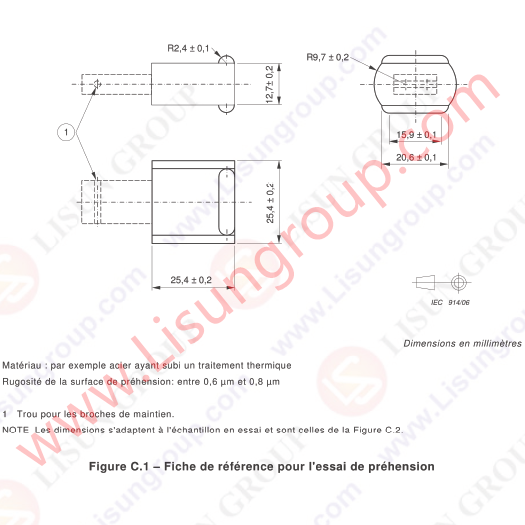

• Fully conforms to NF C 61-314 standard requirements, aligning with Figure C.1 specifications for grip test reference

• Designed to prevent single-pole insertion of 6A and 16A plugs

• Key dimensional tolerances (in millimeters): R2.4±0.1, R9.7±0.2, 15.9±0.1, 20.6±0.1, 25.4±0.2

• Material: Heat-treated steel (or equivalent high-performance material)

• Grip surface roughness: 0.6 μm to 0.8 μm

• Features one retaining pin hole (Trou pour les broches de maintien) for secure fixture during testing

• Dimensional adaptability to test samples, consistent with the requirements of NF C 61-314 Figure C.2

• Manufactured with high precision to maintain dimensional stability and repeatable test results

Test Procedures:

• Inspect the gauge for any damage, corrosion, or dimensional deviations, and confirm its surface roughness and key dimensions comply with NF C 61-314 Figure C.1 specifications.

• Prepare the 6A or 16A plug sample, ensuring it is free from cracks, deformation, or loose components that may affect test results.

• Secure the gauge on a stable fixture using the retaining pin hole to maintain a fixed position during testing.

• Align the plug’s pins with the gauge’s reference openings, attempting to insert only one pin (simulating single-pole insertion) without applying excessive force.

• Observe whether the single pin can be fully inserted into the gauge’s corresponding opening; the test passes if insertion is impossible or restricted as required by the standard.

• Repeat the process with the other pin of the plug to ensure comprehensive verification of single-pole insertion prevention.

• Verify that the plug’s overall grip and pin spacing align with the gauge’s reference dimensions, confirming compliance with NF C 61-314.

• Record test results, documenting whether the plug successfully prevents single-pole insertion (compliant) or not (non-compliant).

• Inspect the gauge and plug for any signs of wear after testing, and reset the setup for subsequent samples to ensure consistency.

Applications:

• Quality control testing of 6A/16A plugs in manufacturing facilities to verify the impossibility of single-pole insertion.

• Compliance assessment by certification bodies and third-party testing laboratories for NF C 61-314 certification of electrical products.

• R&D testing for the design optimization of plugs, ensuring adherence to safety requirements for single-pole insertion prevention.

• Routine inspection of production lines producing household and similar electrical plugs (6A/250V and 16A/250V).

• Dimensional and safety verification of plug components supplied by third-party vendors to meet NF C 61-314 standards.

• Post-production quality audits for electrical plugs to confirm safety performance before market release.

• Quality assurance for manufacturers exporting electrical products to markets requiring NF C 61-314 compliance (e.g., France and French-speaking regions).

Gauge for NF C 61-314 Figure C.1- Reference Sheet for the Grip Test