Product No: GNGPL-S3336

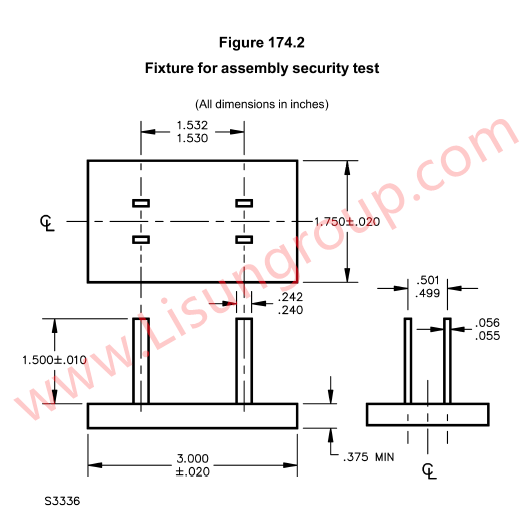

This S3336 Fixture for Assembly Security Test Gauge According to Figure 174.2 of UL 498 is specifically engineered for the assembly security test of attachment plugs and receptacles, strictly adhering to the requirements outlined in Figure 174.2 of the UL 498 standard (“Attachment Plugs and Receptacles”). It is designed to ensure accurate and consistent verification of the assembly security performance of relevant electrical components, helping manufacturers and testing institutions meet the rigorous safety and quality standards set by UL 498. The fixture features precise dimensional specifications to guarantee the reliability and repeatability of test results, making it an essential tool for evaluating whether the assembly structure of plugs and receptacles can withstand intended stresses without compromising safety.

Specifications:

• Complies with UL 498 standard, specifically matching the requirements of Figure 174.2 titled “Fixture for assembly security test”

• All dimensional units are inches

• Key dimensional parameters include: 1.532, 1.530, .242, .240, .056, .055, a minimum value of .375, and 3.000 with a tolerance of ±.020

• Designed for dedicated use in assembly security testing of attachment plugs and receptacles

Test Procedures:

• Prepare the attachment plug or receptacle sample to be tested, ensuring it meets the basic pre-test requirements (e.g., no visible damage, correct assembly as per product specifications).

• Position the test fixture on a stable and level testing platform to avoid external interference affecting test accuracy.

• Secure the sample in the appropriate location relative to the fixture, ensuring the contact points between the sample and the fixture align with the dimensional requirements specified in Figure 174.2 of UL 498.

• Activate the test setup according to the operational guidelines of the assembly security test, applying the required test forces or stresses to the sample through the fixture.

• Monitor the sample’s performance throughout the test, recording key data such as whether the assembly structure remains intact, if there is any loosening of components, or if other abnormal phenomena occur.

• After completing the test, remove the sample from the fixture, conduct a post-test inspection of both the sample and the fixture, and document the test results in accordance with UL 498 standards to confirm whether the sample passes the assembly security test.

Applications:

• Quality control testing in the manufacturing process of attachment plugs and receptacles, used to verify the assembly security of finished products before they leave the factory, ensuring each product meets UL 498 safety standards.

• Compliance testing for manufacturers seeking UL certification for their plug and receptacle products, as the fixture enables accurate testing in line with UL 498 Figure 174.2, a necessary step for obtaining certification.

• R&D testing in the product development phase of electrical component manufacturers, helping engineers evaluate the rationality of assembly designs for new plug and receptacle models and optimize product structures to enhance assembly security.

• Third-party testing laboratories engaged in electrical product safety testing, providing reliable testing tools for conducting impartial and accurate assembly security assessments on plugs and receptacles submitted by clients.

• In-field quality verification for distributors or importers of attachment plugs and receptacles, used to spot-check incoming goods to ensure the purchased products maintain consistent assembly security performance and comply with relevant safety regulations.

S3336 Fixture for Assembly Security Test Gauge According to Figure 174.2 of UL 498