Product No: GNGPL-SB1889C

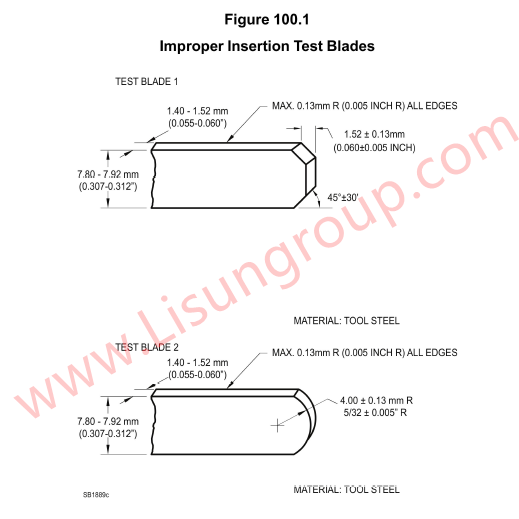

This UL 498 Figure 100.1 Improper Insertion Test Blades consists of two specialized test blades, precision-manufactured in strict compliance with the specifications outlined in UL 498 Figure 100.1. It is designed to evaluate the safety performance of attachment plugs and receptacles by simulating improper insertion scenarios, ensuring that these electrical products can prevent potential hazards (such as electric shock) when subjected to incorrect insertion, thus meeting the rigorous safety standards set by UL 498 for reliable use in household and similar applications.

Specifications:

• Fully conforms to UL 498 standard requirements, aligned with Figure 100.1 specifications for improper insertion testing

• Includes two test blades (Test Blade 1 and Test Blade 2) for comprehensive safety verification

• Material: High-quality tool steel for durability and consistent test performance

• Thickness of both blades: 1.40-1.52 mm (0.055-0.060 inch)

• All edges feature a maximum radius of 0.13 mm (0.005 inch R) for standardized simulation

• Length of both blades: 7.80-7.92 mm (0.307-0.312 inch)

• Key dimensional tolerances for Test Blade 1: 1.52±0.13 mm (0.060±0.005 inch) with a 45°30′ angle specification

• Key dimensional tolerances for Test Blade 2: 4.00±0.13 mm radius and 5/32±0.005 inch radius

• Engineered for precise simulation of improper insertion conditions to assess product safety

Test Procedures:

• Inspect the test blades to ensure they are free from damage, corrosion, or deformation, and confirm their dimensions comply with UL 498 Figure 100.1 requirements.

• Prepare the attachment plug or receptacle sample, ensuring it is in good working condition without cracks, loose components, or electrical defects.

• Secure the sample in a stable, non-conductive fixture to prevent movement during testing and ensure operator safety.

• For Test Blade 1: Align the blade with the sample’s socket or plug opening according to the improper insertion angle (45°30′) specified in the standard.

• Apply a steady, controlled force to insert Test Blade 1 into the sample, simulating incorrect usage, and observe whether the blade can penetrate excessively or cause safety hazards (e.g., contact with live parts).

• Repeat the process with Test Blade 2, following the dimensional and positional guidelines for its specific radius and insertion method.

• Record observations, including whether the sample restricts improper insertion effectively, prevents access to live components, and maintains structural integrity.

• Verify if the sample meets the safety requirements of UL 498 based on the test results.

• Document all test data, noting any non-compliance issues and potential safety risks.

Applications:

• Safety compliance testing of attachment plugs and receptacles in manufacturing facilities to ensure resistance to improper insertion.

• UL 498 certification testing conducted by third-party laboratories and certification bodies.

• R&D testing for the design optimization of plugs and receptacles, enhancing safety against incorrect usage.

• Routine quality control inspections on production lines producing electrical connection devices for household and similar applications.

• Safety validation for suppliers of plug and receptacle components to meet industry safety standards.

• Post-production audits to confirm the safety performance of electrical products before market launch.

• Quality assurance for electrical equipment manufacturers integrating UL 498-compliant plugs and receptacles.

UL 498 Figure 100.1 Improper Insertion Test Blades