Product No: GNGPL-57C19AB

This Gauges C19A and C19B of CEE7 for Checking Impossibility of Single-pole Insertion of Plugs into Socket-outlets including two dedicated variants, is precision-engineered in strict compliance with the specifications outlined in IECEE CEE-7, designed exclusively to verify the impossibility of single-pole insertion into socket-outlets. A core safety requirement for electrical connection devices, this verification prevents users from accessing live parts through partial or incorrect plug insertion, thus mitigating electric shock hazards. By simulating standardized single-pole insertion attempts, the gauge set ensures that socket-outlets meet CEE 7’s rigorous safety criteria, safeguarding user safety and ensuring compliance with regional electrical standards.

Specifications:

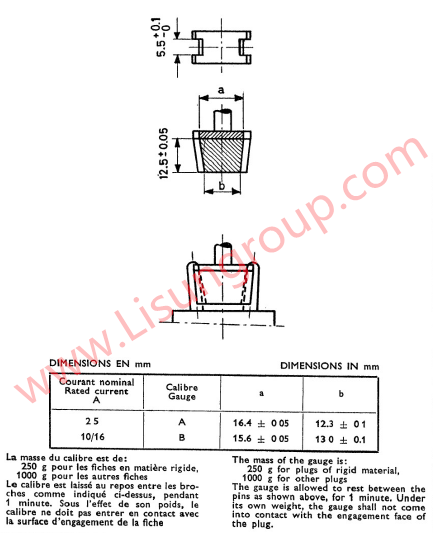

• Fully conforms to IECEE CEE-7 standard requirements for single-pole insertion prevention testing

• Two distinct gauge variants (C19A and C19B) for comprehensive coverage of CEE 7-compliant socket-outlets

• Manufactured from high-precision, durable materials to maintain dimensional stability and repeatable test results

• Engineered with smooth, burr-free surfaces to avoid damaging socket-outlet contacts during testing

• Compatible with CEE 7-compliant domestic and similar-purpose socket-outlets

• Calibrated to replicate the size and shape of standard plug pins for authentic single-pole insertion simulation

Test Procedures:

• Inspect both gauge variants (C19A and C19B) for damage, deformation, or dimensional deviations, confirming compliance with CEE 7 specifications.

• Prepare the socket-outlet sample, ensuring it is clean, free from burrs, loose components, or structural defects that may affect test results.

• Secure the socket-outlet in a stable, flat fixture to maintain consistent positioning during testing.

• For Gauge C19A: Align the gauge with one of the socket-outlet’s live pin openings, attempting to insert it as a single pole (no other pins engaged) with gentle, controlled force.

• Observe whether the gauge can be partially or fully inserted; the test passes if insertion is blocked or restricted as required by CEE 7.

• Repeat Step 4 with the other live pin opening of the socket-outlet to ensure comprehensive verification.

• For Gauge C19B: Repeat the same insertion attempts as Steps 4-6, targeting both live pin openings with the second gauge variant.

• Verify that neither gauge can achieve meaningful insertion (partial or full) in any single-pole configuration, confirming compliance with the standard’s safety requirement.

• Document test results, including observations of insertion resistance and whether the socket-outlet meets CEE 7’s single-pole insertion prevention criteria.

Applications:

• Quality control testing of CEE 7-compliant socket-outlets in manufacturing facilities to verify single-pole insertion prevention.

• Compliance assessment by certification bodies and third-party testing laboratories for IECEE CEE-7 certification of electrical products.

• R&D testing for the design optimization of socket-outlet configurations, enhancing safety against incorrect insertion.

• Routine inspection of production lines producing domestic and similar electrical socket-outlets for regions requiring CEE 7 compliance.

• Performance verification of socket-outlet components supplied by third-party vendors to meet CEE 7 safety specifications.

• Post-production quality audits to confirm user safety by preventing single-pole insertion hazards before market release.

• Quality assurance for manufacturers exporting electrical products to CEE 7-adopting markets, ensuring alignment with regional electrical safety regulations.

Gauges C19A and C19B of CEE7 for Checking Impossibility of Single-pole Insertion of Plugs into Socket-outlets