Product No: GNGPL-57C6

These Gauges C 6 A and C 6 B of CEE 7 are designed in strict compliance with the IECEE CEE-7 standard, dedicated to verifying the installation and fixing compatibility of specific socket-outlets. They ensure that socket-outlets can accommodate proper assembly and secure fixing through precise dimensional validation, supporting reliable performance and safety of electrical connections in domestic and similar scenarios. As essential tools for quality assurance, they play a key role in confirming that sockets meet standard requirements for fixing hole alignment and operational feasibility.

Specifications:

• Complies with IECEE CEE-7 “Specification for plugs and socket-outlets for domestic and similar purpose” C 6

• Available in two variants: C 6 A and C 6 B

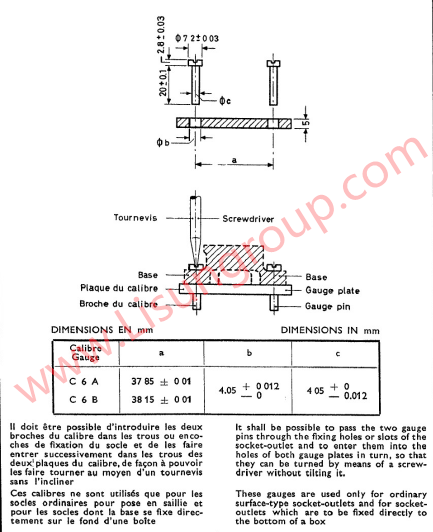

• Dimensional parameters for C 6 A: a = 37.85 ± 0.01 mm, relevant dimensions including 4.05 mm and 8.012 mm (as per specification table)

• Dimensional parameters for C 6 B: a = 38.15 ± 0.01 mm, with specified dimension 0 (as per specification table)

• Additional key dimension: 72 ± 0.03 mm (as indicated in product drawings)

• Enables smooth insertion of two gauge pins through socket fixing holes/slots and subsequent rotation with a screwdriver without tilting

Test Procedures:

• Prepare the socket-outlet to be tested, ensuring it is clean and free of debris that may affect test results.

• Select the appropriate gauge variant (C 6 A or C 6 B) based on the socket type and test requirements.

• Insert the two gauge pins through the fixing holes or slots of the socket-outlet, then guide them into the holes of both gauge plates in sequence.

• Attempt to rotate the gauge pins using a screwdriver, verifying that rotation can be performed smoothly without tilting the pins.

• Confirm that the entire insertion and rotation process meets the standard’s operational requirements to conclude the compatibility test.

Applications:

• Quality control and compliance verification for ordinary surface-type socket-outlets.

• Installation compatibility testing for socket-outlets designed to be fixed directly to the bottom of a box.

• R&D and production inspection processes for socket manufacturers to ensure adherence to IECEE CEE-7 C 6 standards.

• Conformity assessment and performance validation of relevant socket products in third-party testing laboratories.

Gauges C6 Of CEE7