Product No: GNGPL-57C27

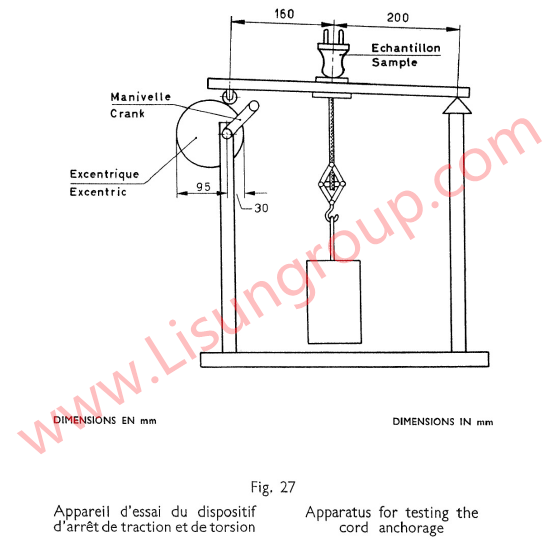

This CEE 7 Fig. 27 Gauges C27 Apparatus for Testing the Cord Anchorage is precision-engineered in strict compliance with the specifications outlined in IECEE CEE-7 Figure 27, a key standard for domestic and similar-purpose plugs and socket-outlets. It is specifically designed to evaluate the reliability of cord anchorage in electrical products, verifying the component’s ability to resist traction and torsion forces. By simulating real-world stress on the cord anchorage, this apparatus ensures that plugs and socket-outlets maintain secure cord retention—preventing loose connections, wire damage, or electric shock hazards—thus meeting the rigorous safety and performance requirements of CEE 7.

Specifications:

• Fully conforms to IECEE CEE-7 standard requirements, aligning with Figure 27 specifications for cord anchorage testing

• Engineered to test both traction and torsion resistance of cord anchorage systems

• Key dimensional specifications (in millimeters): 30mm, 95mm, 160mm, 200mm (as per standard diagram)

• Features a crank (Manivelle) and eccentric (Excentrique) mechanism for controlled force application

• Designed to accommodate standard plugs and socket-outlets for domestic and similar applications

• Manufactured from high-strength, durable materials to withstand repeated testing and maintain structural stability

• Precision-calibrated to ensure consistent force delivery and accurate test results

• Compatible with standard cord types used in CEE 7-compliant electrical products

Test Procedures:

• Inspect the test apparatus for any damage, wear, or mechanical malfunctions, and confirm its dimensions and mechanisms comply with CEE 7 Figure 27 specifications.

• Prepare the test sample (plug or socket-outlet with integrated cord anchorage) and ensure the cord is properly installed and secured per the product’s design.

• Mount the sample securely on the apparatus’s designated fixture, aligning the cord anchorage with the apparatus’s force application points.

• Secure the free end of the cord to the apparatus, ensuring it is taut but not pre-loaded with excessive tension.

• Traction test: Use the crank to apply a controlled axial traction force to the cord, following the force and duration requirements specified in CEE 7.

• Torsion test: Operate the eccentric mechanism to apply a controlled torsional force to the cord, simulating twisting stress as outlined in the standard.

• Observe the cord anchorage during and after both tests, checking for signs of slippage, damage, or reduced retention (e.g., cord movement, loosening of anchorage components).

• Verify if the sample maintains secure cord anchorage without failure, meeting the pass criteria defined in CEE 7.

• Record test results, documenting force values, duration, and any observations of anchorage performance, and classify the sample as compliant or non-compliant.

Applications:

• Quality control testing of plugs and socket-outlets in manufacturing facilities to verify cord anchorage reliability per CEE 7 standards.

• Compliance assessment by certification bodies and third-party testing laboratories for IECEE CEE-7 certification of electrical products.

• R&D testing for the design optimization of cord anchorage systems in plugs and socket-outlets, enhancing resistance to traction and torsion.

• Routine inspection of production lines producing domestic and similar electrical products requiring CEE 7 compliance.

• Performance verification of cord anchorage components supplied by third-party vendors to meet CEE 7 specifications.

• Post-production quality audits to confirm the safety and durability of electrical products before market release in regions requiring CEE 7 compliance.

• Safety validation for electrical equipment manufacturers integrating CEE 7-compliant plugs and socket-outlets with cord anchorage systems.

CEE 7 Fig. 27 Gauges C27 Apparatus for Testing the Cord Anchorage