Product No: GNGPL-57C18

This Gauges C18 of CEE7 for Checking Impossibility of Single-pole Insertion of Plugs is precision-engineered in strict compliance with the specifications outlined in IECEE CEE-7, designed exclusively to verify the impossibility of single-pole insertion of plugs into socket-outlets. A core safety requirement for electrical connection devices, this verification ensures that users cannot access live contact tubes through partial or incorrect plug insertion, thus mitigating electric shock hazards. By simulating standardized single-pole insertion attempts, the gauge ensures that plugs and matching socket-outlets meet CEE 7’s rigorous safety criteria, safeguarding user safety and ensuring compliance with regional electrical standards.

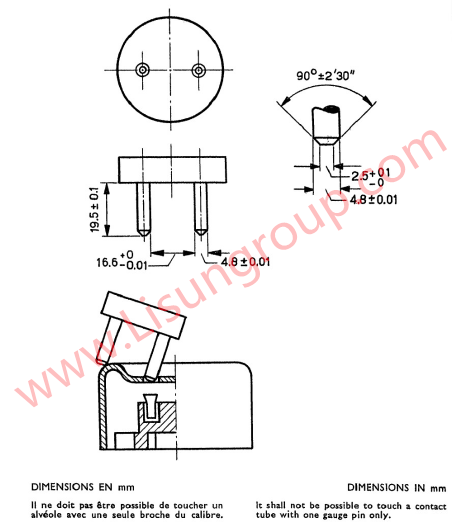

Specifications:

• Fully conforms to IECEE CEE-7 standard requirements for single-pole insertion prevention testing

• Key dimensional parameters (in millimeters): 4.8±0.01 mm (pin diameter), 16.5-0.01 mm (critical length)

• Angular tolerance: 90°±2’30” for pin orientation

• Manufactured from high-precision, durable materials to maintain dimensional stability and repeatable test results

• Engineered with smooth, burr-free pin surfaces to avoid damaging socket-outlet contact tubes during testing

• Designed to replicate standard plug pin profiles for authentic single-pole insertion simulation

• Complies with the core standard requirement: “It shall not be possible to touch a contact tube with one gauge pin only”

• Compatible with CEE 7-compliant domestic and similar-purpose plugs and socket-outlets

Test Procedures:

• Inspect the gauge for damage, deformation, or dimensional deviations, confirming its pin diameter, length, and angular tolerance comply with CEE 7 specifications.

• Prepare the socket-outlet sample, ensuring it is clean, free from burrs, loose components, or structural defects that may affect test results.

• Secure the socket-outlet in a stable, flat fixture to maintain consistent positioning during testing.

• Align one pin of the gauge with a live contact tube opening in the socket-outlet, attempting single-pole insertion with gentle, controlled force (no other pins engaged).

• Observe whether the gauge pin can touch the contact tube or achieve meaningful insertion; the test passes if contact or insertion is blocked.

• Repeat Step 4 with the gauge pin aligned with the other live contact tube opening of the socket-outlet.

• Verify that the gauge cannot touch any contact tube with a single pin, adhering to the core requirement of CEE 7.

• Record observations of insertion resistance and contact tube accessibility, confirming whether the socket-outlet meets the standard’s safety criteria.

• Document test results, noting any non-compliance (e.g., single-pole access to contact tubes) and reset the setup for subsequent samples.

Applications:

• Quality control testing of CEE 7-compliant socket-outlets in manufacturing facilities to verify single-pole insertion prevention.

• Compliance assessment by certification bodies and third-party testing laboratories for IECEE CEE-7 certification of electrical products.

• R&D testing for the design optimization of socket-outlet contact tube layouts, enhancing safety against incorrect insertion.

• Routine inspection of production lines producing domestic and similar electrical socket-outlets for regions requiring CEE 7 compliance.

• Performance verification of socket-outlet components supplied by third-party vendors to meet CEE 7 safety specifications.

• Post-production quality audits to confirm user safety by preventing single-pole insertion hazards before market release.

• Quality assurance for manufacturers exporting electrical products to CEE 7-adopting markets, ensuring alignment with regional electrical safety regulations.

Gauges C18 of CEE7 for Checking Impossibility of Single-pole Insertion of Plugs