Product No: GNGPL-90602

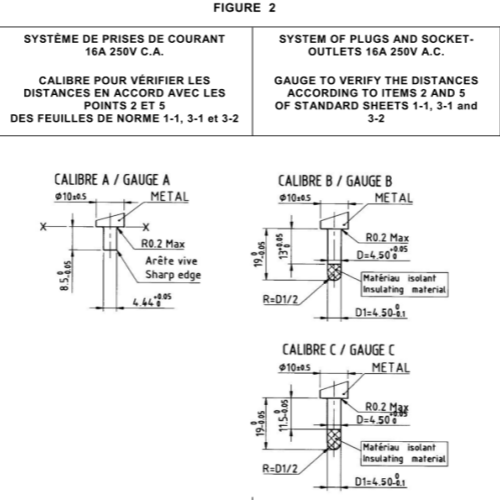

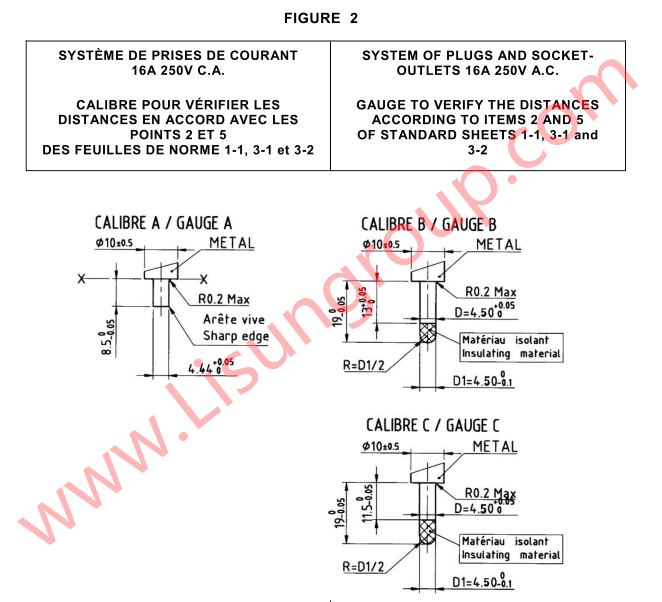

This IEC 60906-1 Figure 2 Gauge for Outlets 16A 250V A.C. is a precision-engineered solution strictly compliant with IEC 60906-1 Figure 2, designed specifically to verify the critical distance requirements of 16A 250V A.C. household and similar-purpose socket-outlets. The kit includes three specialized gauges (Gauge A, Gauge B, Gauge C), each featuring metallic components made from hard, corrosion-resistant metal (e.g., stainless steel) and insulating material elements. By working with a 40V-50V electrical indicator to detect contact, the gauges enable accurate assessment of socket-outlet compliance with standard items 2 and 5—ensuring proper spacing between critical components for electrical safety. As an essential tool for quality assurance, it supports reliable testing for certification, manufacturing control, and R&D in the electrical accessory industry.

Specifications

• Test standard compliance: IEC 60906-1 Figure 2 (for 16A 250V A.C. plugs and socket-outlets)

• Kit composition: 3 specialized gauges (Gauge A, Gauge B, Gauge C)

• Metallic component specifications: ϕ10 ± 0.5 mm; hard, corrosion-resistant metal (e.g., stainless steel); maximum R0.2 mm rounded edges; sharp edge design (as specified)

• Key dimensional parameters: D = 4.50 mm; D1 = 4.50 – 0.1 mm; R = D1/2; 4.44 +0.05 mm (critical dimensions per standard)

• Insulating material: Included in Gauge A, Gauge B, and Gauge C as per structural requirements

• Electrical indicator requirement: Compatible with indicators rated 40 V to 50 V (inclusive) for contact detection

• Core function: Verifies compliance with distance requirements specified in IEC 60906-1 standard sheets 1-1, 3-1, and 3-2 (items 2 and 5)

• Compatibility: Tailored for 16A 250V A.C. household and similar-purpose socket-outlets

Test Procedures

• Inspect all three gauges (A, B, C) for structural integrity: verify metallic components are free of corrosion, deformation, or damage; check insulating material for cracks; confirm dimensional accuracy of key features.

• Prepare the 16A 250V A.C. socket-outlet to be tested, ensuring it is clean, debris-free, and installed in a stable position with shutters held open.

• Connect a functional 40V-50V electrical indicator to the metallic components of the first gauge (Gauge A) as specified.

• Insert Gauge A through the entry holes of the socket’s contact assembly in all possible positions until Plane XX fully contacts the socket’s engagement face; confirm the electrical indicator does not illuminate.

• Disconnect the indicator from Gauge A and connect it to Gauge B, ensuring a secure electrical connection.

• Fully insert Gauge B’s pins into the socket-contact assembly; verify the electrical indicator illuminates as required by the standard.

• Switch the indicator connection to Gauge C, then fully insert Gauge C’s pins into the socket-contact assembly; confirm the indicator does not illuminate.

• Repeat the insertion tests for each gauge in multiple orientations to ensure comprehensive coverage of all possible positions.

• After completing all tests, inspect the socket-outlet and gauges for any signs of wear, damage, or misalignment caused by the testing process.

• Document test results (indicator status for each gauge, insertion positions) and compare against IEC 60906-1 requirements to assess the socket-outlet’s compliance with distance specifications.

Applications

• Compliance testing of 16A 250V A.C. household socket-outlets to verify distance requirements per IEC 60906-1 Figure 2.

• Safety performance evaluation of commercial and similar-purpose 16A 250V A.C. socket-outlets.

• Quality control inspections in manufacturing facilities producing socket-outlets for markets adhering to IEC 60906-1 standards.

• Certification testing conducted by third-party laboratories and regulatory bodies to confirm product conformity.

• R&D testing for optimizing the design and component spacing of 16A 250V A.C. socket-outlets.

• Pre-shipment quality verification for exporters, ensuring products meet international safety requirements for critical distance specifications.

• Routine safety audits for electrical accessory brands to maintain consistent product safety and performance standards.

• Training and calibration of testing personnel in IEC 60906-1 compliant distance verification test procedures.

IEC 60906-1 Figure 2 Gauge for Outlets 16A 250V A.C.

© Copyright 2003 | Blog | Privacy

surge generator | emc test system | emi receiver | electrical safety tester | temperature chamber | salt spray test | environmental chamber | Sitemap

中文简体

中文简体