Product No: GNGPL-5402B

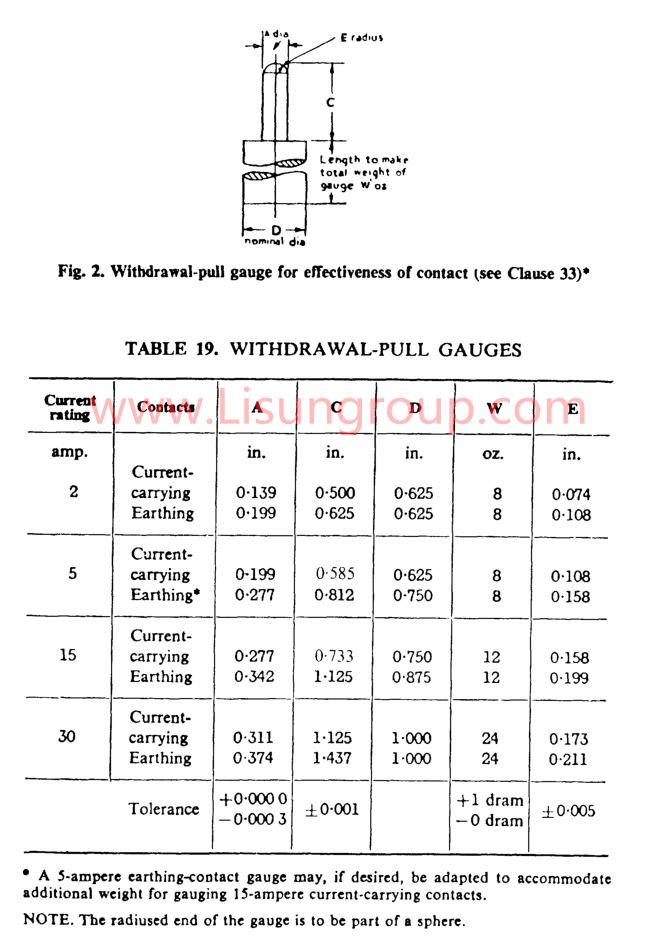

5A Withdrawal-Pull Gauge for Effectiveness of Contact Dia. 0.277 in. 8 oz for BS 546 Figure 2 is a precision testing tool tailored to evaluate the contact effectiveness, structural compliance, and dimensional accuracy of 5A plugs and sockets in accordance with BS 546 standards, as detailed in Figure 2 of BS 546 (“Two-pole and earthing-pin plugs, socket-outlets and adaptors. Specification”). It utilizes a withdrawal-pull method to validate critical contact performance, strictly adhering to the standard’s requirements for dimensions, tolerances, material properties, hardness, and surface roughness. With a material hardness exceeding 50HRC and a low thermal expansion coefficient, the gauge ensures exceptional dimensional stability and reliable testing results, making it an essential instrument for verifying the quality of 5A electrical connection components.

Specifications

• Compliance standard: BS 546 (“Two-pole and earthing-pin plugs, socket-outlets and adaptors. Specification”) Figure 2

• Application rating: 5A

• Core function: Assesses contact effectiveness via withdrawal-pull testing

• Nominal contact diameter: 0.277 inches

• Gauge capacity: 8 ounces

• Material hardness: Over 50HRC

• Material thermal expansion coefficient: Low

• Key attributes (dimensions, tolerances, material, surface roughness): Fully compliant with BS 546 standard requirements

• Dimensional stability: Stable and reliable due to low thermal expansion coefficient

• Design features: Radiused end forming part of a sphere; Includes specified E radius as per standard

• Tolerances: Conforms to BS 546 Table 19 requirements (+0.0000/-0.0003 in. for diameter, ±0.001 in. for relevant dimensions, +1 dram/-0 dram for weight, ±0.005 in. for auxiliary parameters)

• Adaptability option: May be modified to accommodate additional weight for testing 15-ampere current-carrying contacts (per standard note)

Test Procedures

• Prepare the 5A plug or socket sample for testing, ensuring it is free from damage, dirt, corrosion, or debris that could compromise contact effectiveness or test accuracy.

• Inspect the gauge to confirm its surface is clean, free from wear or deformation, the radiused end is intact (as part of a sphere), and its nominal diameter (0.277 in.) and weight (8 oz) meet BS 546 Figure 2 and Table 19 specifications.

• Align the gauge with the sample’s target contact (earthing contact for 5A applications) in strict accordance with Clause 33 of the BS 546 standard.

• Insert the gauge into the sample’s contact slot smoothly, simulating the connection of a standard 5A plug or socket to ensure proper engagement.

• Apply the calibrated withdrawal force corresponding to the gauge’s 8-ounce capacity, following the standard’s prescribed method to assess the sample’s contact retention capability.

• Monitor the withdrawal process to verify that the sample maintains consistent contact and structural integrity, with no excessive looseness or resistance indicating non-compliance.

• Cross-check the sample’s contact dimensions and retention performance against the gauge’s calibrated parameters and BS 546 tolerance requirements.

• If adapting the gauge for 15-ampere current-carrying contact testing (per standard note), add the specified additional weight before repeating steps 3-7.

• Document the test results comprehensively, noting any deviations in contact effectiveness, dimensional conformity, or retention performance.

• Conclude whether the sample meets BS 546 standards based on the gauge’s inspection outcomes.

Applications

• Contact effectiveness testing of 5A plugs and sockets (focus on earthing contacts) to verify compliance with BS 546 Figure 2 and Table 19 requirements.

• Dimensional and structural conformity inspection of 5A two-pole and earthing-pin electrical connection components in the electronics industry.

• Quality control and compliance verification in the electrical appliance industry to ensure the safety, reliability, and contact performance of 5A plug-and-socket assemblies.

• R&D and production quality assurance for manufacturers of 5A plugs, socket-outlets, and adaptors compliant with BS 546 standards.

• Conformity assessment for electrical component manufacturers requiring adherence to BS 546 specifications for contact effectiveness.

• Routine inspection of 5A plug and socket contacts in commercial, industrial, or residential applications relying on BS 546-compliant electrical systems.

• Modified testing of 15-ampere current-carrying contacts (with additional weight) for manufacturers producing multi-rating electrical connection products.

• Performance validation of contact retention for 5A electrical components to ensure long-term usability and safety.

5A Withdrawal-Pull Gauge for Effectiveness of Contact Dia. 0.277 in. 8 oz for BS 546 Figure 2