Product No: GNGPL-6218

This DIN-VDE 0620-1 Lehre 18 Prüfung von Rillen, Löchern und Hinterschneidungen is specifically designed to test the presence of grooves, holes, and undercuts in fixed sockets, strictly adhering to the requirements of the DIN VDE 0620-1 standard. It serves as a critical quality verification tool for sockets used in household and similar applications, ensuring that the socket structure does not have unintended grooves, holes, or undercuts that could compromise safety, affect plug connection stability, or lead to potential hazards such as debris accumulation or structural weakness.

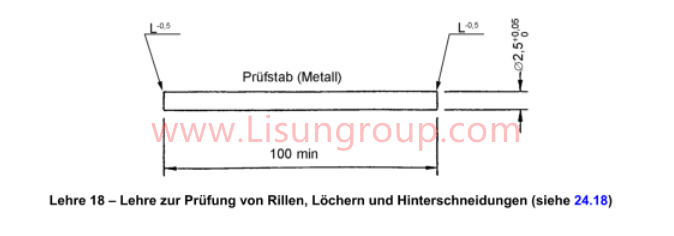

Specifications:

• Complies with DIN VDE 0620-1 “Stecker und Steckdosen für den Hausgebrauch und ähnliche Anwendungen – Teil 1: Allgemeine Anforderungen an ortsfeste Steckdosen” Lehre 18

• Test probe material: Metal (Prüfstab (Metall))

• Minimum length specification: 100 mm (100 min)

• Dimension tolerance: -0.5 (relevant to probe or test feature)

Test Procedures:

• Prepare the fixed socket under test, ensuring it is in a clean, unused condition without visible external damage.

• Inspect the gauge to confirm it meets the specified material and dimension requirements, ensuring no deformation or wear.

• Position the metal test probe of the gauge at the opening and key contact areas of the socket, in accordance with the standard’s testing guidelines.

• Gently insert and maneuver the probe to check for grooves, holes, or undercuts in all critical regions of the socket’s internal and external structure.

• Verify that the probe does not catch on or fit into any unintended grooves, holes, or undercuts beyond the standard’s allowable limits.

• Record observations of any detected non-compliant features (grooves, holes, undercuts) during the test.

• Determine if the socket passes the test based on whether it conforms to the standard’s requirements for the absence of unacceptable grooves, holes, and undercuts.

Applications:

• Quality control testing of fixed household sockets during manufacturing to ensure structural compliance.

• Compliance verification for sockets used in commercial, office, or public facility electrical systems.

• Routine inspection in socket production facilities to prevent structural defects in batch production.

• Conformity assessment by certification bodies and third-party testing laboratories.

• R&D and design validation for socket manufacturers, ensuring structural integrity meets standard requirements.

• Safety audits and maintenance checks for electrical systems in residential buildings, hotels, and industrial workshops.

• Pre-shipment inspection of sockets to ensure they meet global market access standards.

DIN-VDE 0620-1 Lehre 18 Prüfung von Rillen, Löchern und Hinterschneidungen