Product No: GNGPL-6210A

This DIN-VDE 0620-1-Lehre 10a Prüfung auf Unmöglichkeit des einpoligen Einführens A is engineered to meet the requirements of Lehre 10a in the DIN VDE 0620-1 standard (“Plugs and Sockets for Household and Similar Applications – Part 1: General Requirements for Fixed Sockets”) and is also aligned with DIN VDE 0620-2-1 (2021-02). Its core function is to test the “impossibility of single-pole insertion” in fixed sockets—a critical safety feature that prevents accidental insertion of a single electrical pole (which could expose users to live components and electrical shock hazards). With precise dimensional and angular design, the gauge ensures accurate validation of a socket’s anti-single-pole-insertion mechanism, making it an essential tool for manufacturers, testing laboratories, and quality assurance teams committed to adhering to DIN VDE safety standards for household and similar sockets.

Specifications:

• Complies with DIN VDE 0620-1 standard, specifically designed for Lehre 10a (testing the impossibility of single-pole insertion)

• Aligns with the technical requirements of DIN VDE 0620-2-1 (2021-02) to ensure up-to-date compliance

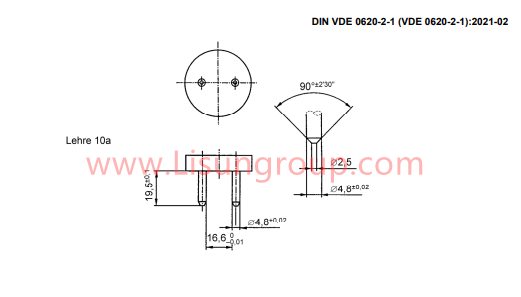

• Features a critical angular specification of 90° ± 2’30” (90 degrees plus or minus 2 minutes and 30 seconds), ensuring proper simulation of single-pole insertion attempts

• Incorporates two key diameter (ø) parameters, both specified as 4.8 mm with a tolerance of ±0.02 mm, to match the dimensional constraints of socket pole openings

• Includes a length dimension of 16.6 mm with a tolerance of ±0.1 mm, ensuring the gauge interacts with the socket’s internal safety mechanism as intended

• Core purpose: Verifies that fixed sockets block the insertion of the gauge (simulating single-pole access) to prevent electrical safety risks

Test Procedures:

• Prepare the fixed socket sample for testing, ensuring it is free from visible damage, assembled correctly according to product specifications, and meets pre-test conditions outlined in DIN VDE 0620-1.

• Position the socket sample on a stable, level testing platform, ensuring the socket’s insertion openings are easily accessible and aligned horizontally (to replicate typical user interaction).

• Inspect the gauge to confirm its dimensions (diameter, length, angle) are within the specified tolerances and that it is free from wear or deformation that could affect test accuracy.

• Hold the gauge at the specified 90° angle relative to the socket’s insertion opening, aligning one of the 4.8 mm diameter sections with a single pole opening of the socket. Gently attempt to insert the gauge into the opening, applying only moderate, hand-applied force (consistent with typical user insertion effort).

• Observe whether the gauge penetrates into the socket: A passing test requires the socket’s anti-single-pole-insertion mechanism to block the gauge from being inserted (i.e., no full or partial penetration that would indicate a safety flaw).

• Repeat steps 4–5 for all single pole openings on the socket sample (if applicable). After testing, document the results (pass/fail) and inspect both the gauge and socket for any damage, ensuring compliance with DIN VDE 0620-1 Lehre 10a.

Applications:

• Quality control testing in the manufacturing of fixed sockets for household and similar use, used to verify that each finished socket’s anti-single-pole-insertion mechanism works as required by DIN VDE standards, preventing defective products from reaching the market.

• Compliance testing for socket manufacturers seeking DIN VDE certification, as the gauge enables mandatory validation of the anti-single-pole-insertion feature— a key requirement for meeting DIN VDE 0620-1 and accessing markets that enforce European electrical safety regulations.

• R&D testing in the development of new fixed socket models, helping engineers design and optimize anti-single-pole-insertion mechanisms, validate the effectiveness of different safety structures, and ensure new products meet DIN VDE standards from the prototype stage.

• Third-party testing laboratories conducting impartial safety assessments of fixed sockets, providing a standardized tool to objectively evaluate whether client-submitted sockets block single-pole insertion, supporting regulatory compliance and consumer safety.

• Incoming quality inspection for distributors or importers of fixed sockets (especially those targeting European markets), used to spot-check batches of purchased products to confirm their anti-single-pole-insertion function complies with DIN VDE 0620-1 Lehre 10a, reducing safety risks and non-compliance costs.

DIN-VDE 0620-1-Lehre 10-A Prüfung auf Unmöglichkeit des einpoligen Einführens A