Product No: GNGPL-6201

This DIN-VDE 0620-1-Lehren 1 Größe der Steckerstift-Einführungsöffnungen is engineered to meet the requirements of Lehre 1 in the DIN VDE 0620-1 standard (“Plugs and Sockets for Household and Similar Applications – Part 1: General Requirements for Fixed Sockets”). It is dedicated to testing the size of plug pin insertion openings in sockets, a critical parameter that ensures proper mating between plugs and sockets while preventing safety hazards such as loose connections or incorrect pin insertion. The gauge is available in three variants (1a, 1b, 1c) to accommodate different socket materials and additional DIN standards, ensuring precise and compliant testing across various application scenarios. It serves as an essential tool for manufacturers, testing laboratories, and quality assurance teams focused on meeting the strict safety and dimensional standards of DIN VDE 0620-1 for household and similar sockets.

Specifications:

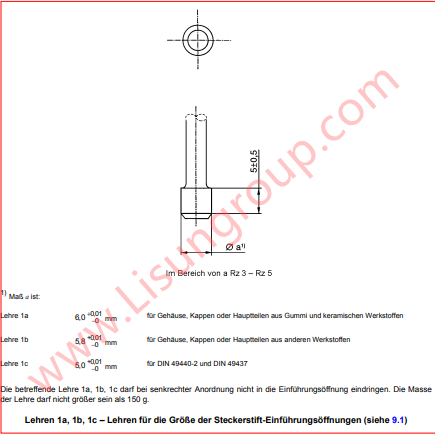

• Complies with DIN VDE 0620-1 standard, specifically designed for Lehre 1 (“Gauge for the size of plug pin insertion openings”) as referenced in clause 9.1 of the standard

• Available in three specialized variants to match different testing needs:

• Variant 1a: Features a diameter (ø a) of 6.0 mm with a tolerance of -0/+0.01 mm, intended for sockets with housings, caps, or main parts made of rubber and ceramic materials

• Variant 1b: Features a diameter (ø a) of 5.8 mm with a tolerance of -0/+0.01 mm, designed for sockets with housings, caps, or main parts made of other materials (excluding rubber and ceramic)

• Variant 1c: Features a diameter (ø a) of 6.0 mm with a tolerance of -0/+0.01 mm, specified for use with products conforming to DIN 49440-2 and DIN 49437 standards

• Maximum allowable mass of the gauge: 150 grams, ensuring consistent testing pressure without damaging socket components

• Core function: Verifies that socket insertion openings do not allow the gauge to penetrate when positioned vertically (per DIN VDE 0620-1 requirements)

Test Procedures:

• Prepare the fixed socket sample for testing, ensuring it is free from visible damage, assembled correctly according to product specifications, and meets pre-test conditions defined by DIN VDE 0620-1.

• Select the appropriate gauge variant (1a, 1b, or 1c) based on the socket’s material (rubber/ceramic, other materials) or compliance with DIN 49440-2/DIN 49437 (for variant 1c).

• Position the socket sample on a stable, level testing platform, ensuring the plug pin insertion opening to be tested is aligned vertically (to meet the standard’s vertical arrangement requirement).

• Hold the selected gauge vertically above the socket’s insertion opening, ensuring the gauge is centered and not tilted. Gently lower the gauge toward the opening without applying additional force (relying only on the gauge’s own weight, which must not exceed 150 g).

• Observe whether the gauge penetrates into the socket’s insertion opening. Record the result: a passing test requires the gauge to not penetrate the opening.

• After testing one opening, repeat steps 3–5 for all other plug pin insertion openings on the socket sample (if applicable). Inspect the gauge and socket for any signs of damage post-test, then document the results to confirm compliance with DIN VDE 0620-1 Lehre 1.

Applications:

• Quality control testing in the manufacturing of fixed sockets for household and similar applications, used to verify that insertion opening sizes meet DIN VDE 0620-1 standards before products leave the factory, ensuring safe and proper plug-socket mating.

• Compliance testing for socket manufacturers seeking certification to DIN VDE 0620-1, as the gauge enables accurate validation of insertion opening dimensions— a mandatory requirement for meeting the standard and accessing markets that enforce DIN VDE regulations.

• R&D testing in the development of new fixed socket models, helping engineers optimize the design of insertion openings, validate compatibility with different plug types, and ensure new products align with DIN VDE 0620-1 requirements from the early design stage.

• Third-party testing laboratories conducting impartial safety and compliance assessments of fixed sockets, providing a standardized tool to objectively evaluate insertion opening sizes for clients (e.g., manufacturers, retailers, regulatory bodies).

• Incoming quality inspection for distributors or importers of fixed sockets, used to spot-check batches of purchased products to confirm their insertion openings meet DIN VDE 0620-1 Lehre 1 specifications, ensuring consistent product safety and compliance across inventory.

DIN-VDE 0620-1-Lehren 1 Größe der Steckerstift-Einführungsöffnungen