Product No: GNGPL-3612

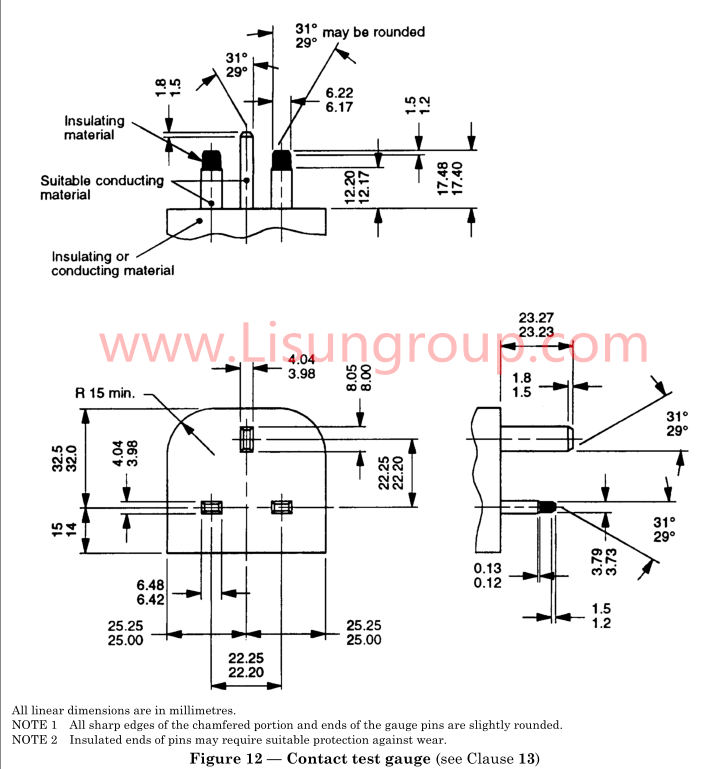

Contact Test Gauge According to BS 1363-2 Figure 12 is engineered to assess the structural and dimensional compliance of plugs and sockets with the BS 1363-2 standard, as specified in Figure 12 of the standard. It adheres strictly to the standard’s requirements for critical attributes including dimensions, tolerances, material quality, hardness, and surface roughness, ensuring consistent and accurate testing outcomes. With a low thermal expansion coefficient and reliable dimensional stability, the gauge delivers dependable performance for quality verification in relevant industries.

Specifications

• Compliance standard: BS 1363-2 (13 A plugs, socket-outlets, adaptors and connection units – 13 A switched and unswitched socket-outlets. Specification) Figure 12

• Material hardness: Exceeds 50HRC

• Material thermal expansion coefficient: Low

• Linear dimensions: All specified in millimetres

• Gauge pin features: Slightly rounded sharp edges on chamfered portions and pin ends

• Insulated pin protection: Insulated ends may require appropriate wear-resistant protection

• Key attributes (dimensions, tolerances, material, surface roughness): Fully compliant with BS 1363-2 standard requirements

Test Procedures

• Prepare the plug or socket sample for testing, ensuring it is free from damage, dirt, or debris that could interfere with test accuracy.

• Inspect the test gauge to confirm its surface is clean, free from wear or deformation, and that insulated ends (if applicable) are properly protected.

• Align the gauge with the sample’s contact points and structural features in strict accordance with the requirements outlined in BS 1363-2 Figure 12 and Clause 13.

• Verify the gauge’s smooth engagement with the sample, ensuring no excessive resistance that would indicate structural non-compliance.

• Cross-check the sample’s key dimensions against the gauge’s calibrated specifications to confirm adherence to tolerance limits.

• Document the test results, indicating whether the sample meets the BS 1363-2 standard based on the gauge’s inspection findings.

Applications

• Dimensional and structural compliance testing of plugs and sockets against BS 1363-2 Figure 12 requirements.

• Quality control and inspection processes in the electronics industry for plug-and-socket components.

• Compliance verification in the electrical appliance industry to ensure the safety and compatibility of plug-and-socket assemblies.

• R&D and production quality assurance for manufacturers of 13 A plugs, socket-outlets, adaptors, and related connection units.

• Conformity assessment in industries producing electrical connection products requiring adherence to BS 1363-2 standards.

Contact Test Gauge – BS 1363-2 Figure 12