Product No: GNGPL-235C7

This professional testing gauge is developed in strict accordance with CEI 23-50 Normalization Sheet C7, and it is specifically engineered to verify the interchangeability between S30, S31, S32 plugs and P30 sockets. Featuring a stably assembled integrated structure, the gauge ensures that the tested plugs can fully insert into the matching gauge (simulating P30 sockets) without excessive force, which is critical for guaranteeing the compatibility and reliable electrical connection of plug and socket products, as well as eliminating potential safety risks caused by poor interchangeability. It is an essential testing device for enterprises and institutions engaged in the production, quality control and compliance certification of household and similar electrical plug and socket components.

Specifications

• Complies with CEI 23-50 Normalization Sheet C7 standard requirements

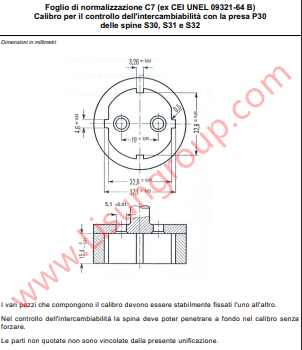

• Has key dimensional parameters including 3.26±0.08 mm, 4.60/3.26 mm, 32.6±0.08 mm, 37.1±0.08 mm, 5.1±0.01 mm and 15.4 mm

• Adopts a firmly fixed integrated structure, with all components stably assembled to avoid loosening during testing

• Is dedicated to verifying the interchangeability of S30, S31 and S32 plugs with P30 sockets

• Requires that the tested plugs can fully penetrate the gauge without forced operation to meet interchangeability criteria

• Features high dimensional accuracy and structural stability to maintain consistent test results after repeated applications

Test Procedures

• Prepare the gauge and the to-be-tested S30, S31 and S32 plugs, ensuring that both the gauge and plug surfaces are clean, free of burrs, deformation or rust that may interfere with test accuracy.

• Confirm that all components of the gauge are stably fixed and that there is no structural looseness that could affect the test.

• Take one of the tested plugs, align it with the gauge’s detection port according to the normal use orientation, and attempt to insert the plug into the gauge.

• Observe and check whether the plug can fully penetrate the gauge without applying excessive force; record the insertion smoothness and depth as core test data.

• Repeat steps 3-4 for all S30, S31 and S32 plugs to complete the full range of interchangeability tests for specified plug types.

• Judge whether the plugs meet the interchangeability requirements based on the test results, and sort out the compliance status of each plug sample.

• After finishing all tests, clean the gauge’s detection port and the plug surfaces, and store the gauge in a dry, dust-free environment to preserve its testing precision.

Applications

• Production line quality inspection of plug and socket manufacturers, where the gauge is used to conduct batch sampling or full inspection of S30/S31/S32 plugs to ensure their interchangeability with P30 sockets meets standard requirements.

• Compliance certification testing of electrical plug and socket products by third-party testing institutions, using the gauge to verify whether the products conform to relevant Italian safety and quality standards for interchangeability.

• R&D and structural optimization of plug and socket products, applying the gauge to validate the rationality of new plug or socket structural designs and adjust mold parameters according to test results to improve interchangeability.

• Market supervision and spot-check work of regulatory departments, utilizing the gauge to inspect the interchangeability of plugs and sockets on the market and remove unqualified products that may cause connection failures or safety hazards.

CEI-23-50 Foglio di normalizzazione C7 (ex CEI UNEL 09321-64 B) Calibro per il controllo dell’intercambiabilita con la presa P30 delle spine S30, S31 e S32