Product No: GNGPL-235C5

This CEI-23-50 Foglio di normalizzazione C5 (ex CEI UNEL 09319-64 2A e 2B) Calibri per il controllo dello scartamento degli spinotti delle spine S30, S31 e S32 is a set of specialized calibration gauges designed to inspect the pin spacing of S30, S31, and S32 plugs, strictly complying with CEI 23-50 standard (formerly CEI UNEL 09319-64 2A and 2B). It serves as a critical quality control tool for plugs used in household and similar applications, ensuring that the internal and external spacing of plug pins meets precise dimensional requirements. Accurate pin spacing is essential for reliable compatibility with matching sockets, stable electrical contact, and the prevention of connection failures or safety hazards.

Specifications:

• Complies with CEI 23-50 “Spine e prese per usi domestici e similari – Parte 1: Prescrizioni generali” C5 (ex CEI UNEL 09319-64 2A e 2B)

• Application scope: Dedicated to inspecting pin spacing of S30, S31, and S32 plugs

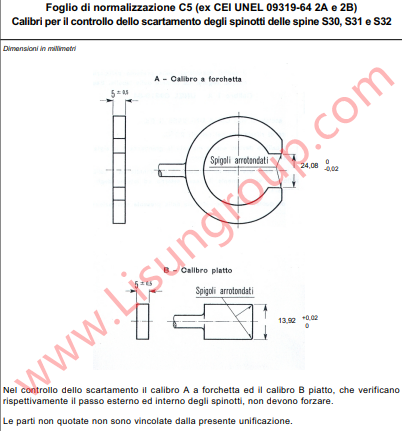

• Gauge types: Fork gauge (Calibro a forchetta, Type A) and flat gauge (Calibro platto, Type B)

• Fork gauge (Type A) dimensions (mm):

• Curved prongs (Spigli arcantati): 24.08-0.02

• Rounded prongs (Spigli arrotondati): 13.92+0.02

• Additional dimension: 5±0

• Core function: Fork gauge verifies external pin spacing; flat gauge verifies internal pin spacing

• Key requirement: Neither gauge shall require force during the inspection process

• Unspecified dimensions: Not constrained by the standard’s unified requirements

Test Procedures:

• Prepare the S30, S31, or S32 plug under test, ensuring its pins are clean, intact, and free from deformation or misalignment.

• Inspect both the fork gauge (Type A) and flat gauge (Type B) to confirm they meet the specified dimensional requirements and have no wear or damage.

• Use the fork gauge (Type A) to check the external spacing of the plug’s pins: Align the gauge’s prongs with the outer edges of the pins and position it without applying force.

• Verify that the fork gauge fits smoothly over the pins without force, confirming the external spacing complies with standards.

• Use the flat gauge (Type B) to check the internal spacing of the plug’s pins: Insert the gauge between the pins in the intended orientation, without forcing it.

• Confirm that the flat gauge fits properly between the pins without force, verifying the internal spacing meets requirements.

• Record the test results; the plug passes if both gauges fit correctly without force, indicating internal and external pin spacing compliance.

Applications:

• Quality control inspection of S30, S31, and S32 plugs during manufacturing processes.

• Compliance verification for plugs used in household, commercial, and office electrical systems.

• Batch product testing in plug production facilities to ensure consistent pin spacing accuracy.

• Conformity assessment by certification bodies and third-party testing laboratories.

• R&D and design validation for plug manufacturers optimizing pin positioning and spacing.

• Pre-shipment inspection of plugs to meet CEI 23-50 standard requirements for market access.

• Compatibility testing between plugs and matching sockets to ensure proper fit and electrical performance.

CEI-23-50 Foglio di normalizzazione C5 (ex CEI UNEL 09319-64 2A e 2B) Calibri per il controllo dello scartamento degli spinotti delle spine S30, S31 e S32