Product No: GNGPL-235C3

This CEI-23-50 Foglio di normalizzazione C3 Calibro “Non Passa”per il controllo dei fori di introduzione degli spinotti nelle prese P30 is a specialized “Non Pass” calibration gauge designed to inspect the pin insertion holes of P30 sockets, strictly complying with the CEI 23-50 standard. It serves as a key quality control tool for household and similar application sockets, ensuring that the size of the socket’s pin insertion holes meets specified requirements. By preventing the gauge from fully entering the holes, it verifies the socket’s structural integrity and compatibility with corresponding plugs, avoiding potential connection instability or safety hazards caused by oversized holes.

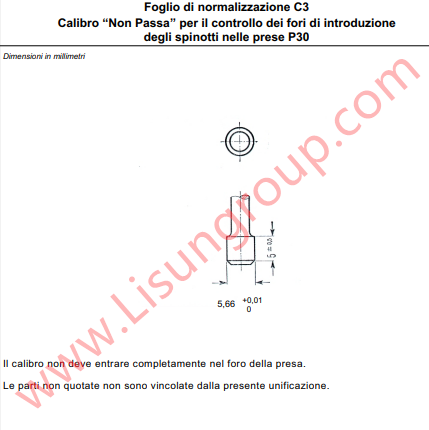

Specifications:

• Complies with CEI 23-50 “Spine e prese per usi domestici e similari – Parte 1: Prescrizioni generali” C3

• Application scope: Dedicated to inspecting pin insertion holes of P30 sockets

• Gauge type: “Non Passa” (Non Pass) gauge

• Key dimension: 5.66+0.01 mm

• Core requirement: The gauge shall not fully enter the socket’s pin insertion holes

• Unspecified dimensions: Not constrained by the standard’s unified requirements

Test Procedures:

• Prepare the P30 socket under test, ensuring it is in a clean, unused condition with no debris or damage in the pin insertion holes.

• Inspect the gauge to confirm it meets the 5.66+0.01 mm dimension requirement and has no deformation or wear.

• Align the gauge with one of the socket’s pin insertion holes in the intended insertion direction.

• Apply a steady and reasonable force to attempt inserting the gauge into the hole.

• Observe whether the gauge can fully enter the pin insertion hole; the test for this hole passes if full insertion is prevented.

• Repeat steps 3-5 for all pin insertion holes on the P30 socket to ensure comprehensive inspection.

• Record the test results; the socket meets the standard if none of the pin insertion holes allow full entry of the gauge.

Applications:

• Quality control inspection of P30 sockets during manufacturing processes.

• Compliance verification for P30 sockets used in household electrical systems.

• Batch product inspection in socket production facilities to ensure consistent hole size accuracy.

• Conformity assessment by certification bodies and third-party testing laboratories.

• R&D and design validation for socket manufacturers optimizing P30 socket pin hole dimensions.

• Pre-shipment inspection of P30 sockets to meet market access standards.

• Routine safety and quality audits for electrical equipment in residential buildings, offices, and public facilities.

CEI-23-50 Foglio di normalizzazione C3 Calibro “Non Passa”per il controllo dei fori di introduzione degli spinotti nelle prese P30