Product No: GNGPL-3629

This BS1363-2 Figure 29 Calibration Jig for Calibrated Link is a specialized tool engineered strictly in accordance with BS 1363-2 Figure 29, designed exclusively for the calibration of calibrated links used in testing 13 A electrical accessories. It features a precision-assembled structure with key components including self-aligning contacts, silver-plated beryllium copper fuse clips, and brass contact plates, ensuring stable and accurate positioning during calibration. The jig’s design incorporates intentional end float and clearance to enable self-alignment of contacts, while soldered joints between critical parts guarantee reliable electrical connectivity. As an essential auxiliary tool for compliance testing, it ensures calibrated links meet the rigorous accuracy requirements of BS 1363-2 standards, supporting quality assurance and certification processes in the electrical accessory industry.

Specifications

• Test standard compliance: BS 1363-2 Figure 29 (dedicated for calibrated link calibration)

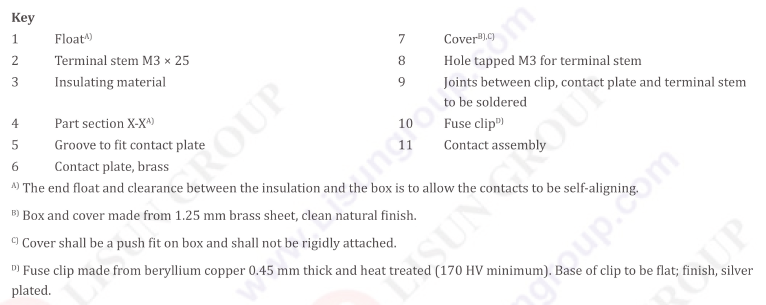

• Core components: Float, terminal stem (M3 × 25), insulating material, brass contact plate, fuse clip, contact assembly, and brass box/cover

• Material specifications: Box and cover made from 1.25 mm brass sheet (clean natural finish); fuse clip from 0.45 mm thick beryllium copper (heat treated to minimum 170 HV, silver-plated, flat base)

• Structural design: Groove to fit contact plate; self-aligning contacts enabled by end float and insulation-box clearance

• Fastening details: Hole tapped M3 for terminal stem installation; cover is a push fit on the box (non-rigidly attached)

• Joint requirements: Soldered connections between clip, contact plate, and terminal stem for stable electrical performance

• Compatibility: Tailored for calibrating links used in testing 13 A plugs, socket-outlets, adaptors, and connection units

Test Procedures

• Inspect the calibration jig for structural integrity, verifying that all components (fuse clip, contact plate, terminal stem) are intact, soldered joints are secure, and the cover fits properly as a push fit.

• Ensure the fuse clip’s silver plating is intact, the base is flat, and the insulating material is free of damage or contamination.

• Install the terminal stem into the M3 tapped hole, securing it firmly to maintain stability during calibration.

• Place the calibrated link to be tested into the jig, aligning it with the brass contact plate and fuse clip to ensure full contact.

• Verify that the calibrated link is properly seated in the groove of the contact plate, and the self-aligning function works smoothly (no binding or misalignment).

• Attach the push-fit cover to the box, ensuring it is not rigidly fixed and allows for proper contact alignment.

• Connect the calibration jig to relevant measurement equipment to monitor electrical parameters (e.g., resistance, conductivity) of the calibrated link.

• Initiate the calibration process in accordance with BS 1363-2 protocols, recording key data to assess the calibrated link’s accuracy.

• Adjust the calibrated link as needed based on measurement results, ensuring it meets the standard’s specified requirements.

• After calibration is complete, remove the cover, carefully take out the calibrated link, and inspect the jig for any signs of wear or damage before storage.

Applications

• Calibration of calibrated links used in testing 13 A fused plugs, socket-outlets, and connection units compliant with BS 1363-2 standards.

• Quality control in manufacturing facilities producing calibrated links, ensuring they meet precision requirements for electrical testing.

• Compliance support for third-party laboratories and regulatory bodies conducting certification testing of 13 A electrical accessories.

• R&D testing for optimizing the design and performance of calibrated links used in BS 1363-2 compliant test setups.

• Routine calibration maintenance of test equipment in electrical accessory production facilities to ensure consistent test accuracy.

• Pre-shipment verification of calibrated links for exporters, ensuring compatibility with BS 1363-2 test requirements in target markets.

• Technical support for electrical testing labs to maintain the reliability and accuracy of their BS 1363-2 compliant test processes.

BS1363-2 Figure 29 Calibration Jig for Calibrated Link

BS1363-2 Figure 29 Calibration Jig for Calibrated Link