Product No: GNGPL-3628

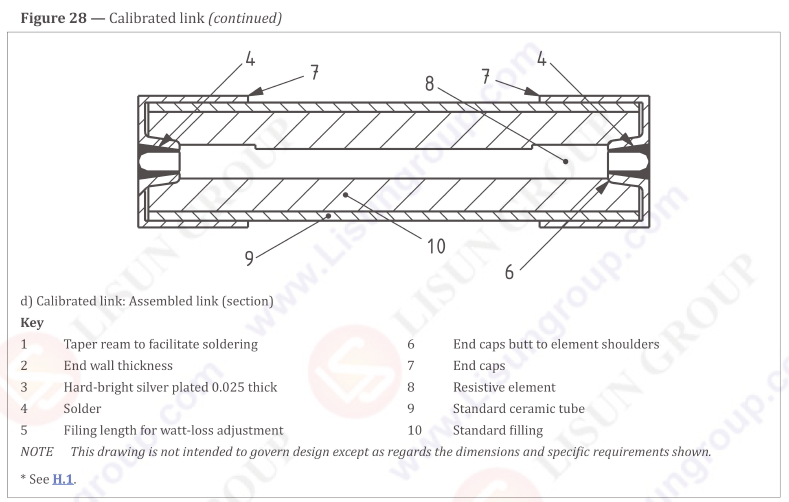

This Calibrated Link (Continued) Required by BS1363-1 Figure 28 is a precision-engineered test component exclusively developed to meet the requirements of BS 1363-1 Figure 28, specifically tailored for performance testing of 13 A rewirable and non-rewirable fused plugs, socket-outlets, adaptors, and connection units. It features a sophisticated assembled structure with key components including a resistive element, standard ceramic tube, end caps, and filling, complemented by hard-bright silver plating and a taper ream design for easy soldering. The product enables accurate watt-loss adjustment through a dedicated filing length, ensuring consistent and reliable test conditions that align with international electrical safety and performance standards, making it an essential tool for compliance verification and quality assurance in the electrical accessory industry.

Specifications

• Test standard compliance: BS 1363-1 Figure 28 (applicable to 13 A fused plugs, socket-outlets, adaptors, and connection units)

• Core structure: Assembled design including resistive element, standard ceramic tube, end caps, and standard filling

• Plating specification: Hard-bright silver plating with a thickness of 0.025 (units as per standard)

• Soldering facilitation: Taper ream feature to simplify soldering operations

• Adjustable function: Dedicated filing length for watt-loss adjustment

• Structural details: End caps butt to element shoulders; end wall thickness meets standard-specified requirements

• Design principle: Dimensions and specific requirements strictly follow BS 1363-1 Figure 28 (non-design-governing beyond specified parameters)

• Compatibility: Optimized for 13 A rewirable and non-rewirable fused plugs and related electrical accessories

Test Procedures

• Confirm the test objectives and ensure the calibrated link is compatible with the 13 A electrical accessory (plug, socket-outlet, adaptor, or connection unit) to be tested.

• Inspect the calibrated link for structural integrity, verifying that end caps are properly butted to element shoulders, the silver plating is intact, and there is no damage to the ceramic tube or resistive element.

• Adjust the watt-loss of the calibrated link using the dedicated filing length as required by the BS 1363-1 test protocol, ensuring precise calibration.

• Use the taper ream feature to solder the calibrated link to the test sample’s designated terminals, ensuring a secure and stable electrical connection.

• Mount the assembled test sample (with the calibrated link installed) into a suitable test fixture, ensuring proper alignment and stability for the duration of the test.

• Connect the test setup to relevant measurement equipment to monitor electrical parameters such as watt-loss, current, and voltage throughout the test.

• Initiate the test in accordance with BS 1363-1 procedures, maintaining the specified test conditions (e.g., voltage, duration) as required.

• Continuously monitor the test process to record data related to watt-loss and other key performance indicators, ensuring the calibrated link functions consistently.

• Upon completion of the test, disconnect the power supply and carefully remove the calibrated link from the test sample.

• Inspect the calibrated link and test sample for any signs of damage or deformation, then compare the recorded data against BS 1363-1 standards to assess compliance.

Applications

• Compliance testing of 13 A rewirable fused plugs to validate performance against BS 1363-1 standards.

• Performance verification of 13 A non-rewirable fused plugs, ensuring adherence to specified watt-loss and electrical safety requirements.

• Quality control inspections in manufacturing facilities producing 13 A socket-outlets, adaptors, and connection units for BS 1363-1 compliant markets.

• Certification testing conducted by third-party laboratories and regulatory bodies to confirm product conformity.

• R&D testing for optimizing the electrical performance and design of 13 A fused plugs and related electrical accessories.

• Pre-shipment quality checks for exporters, ensuring products meet the technical requirements of target markets following BS 1363-1 specifications.

• Calibration and validation of electrical testing equipment used for evaluating 13 A plug-and-socket systems.

• Routine performance audits for electrical accessory brands to maintain consistent product quality and safety standards.

Calibrated Link (Continued) Required by BS1363-1 Figure 28