Product No: GNGPL-3605

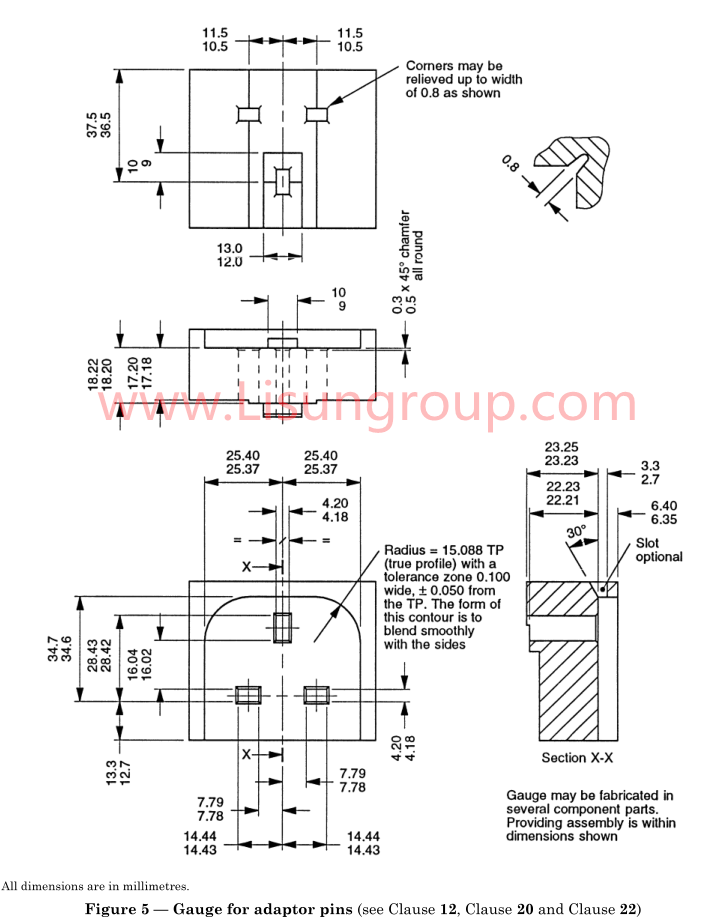

Gauge for Adaptor Pins According to BS 1363-3 Figure 5 is engineered specifically to verify the compliance of adaptor pins with BS 1363-3 Figure 5 requirements, focusing on critical parameters such as the relative position of pins, pin length, and the fit of the pin-plug joint surface. It boasts strict adherence to standard specifications for dimensions, tolerances, and material properties, delivering stable and accurate testing results to support quality control and compliance verification in related industries.

Specifications:

• Complies with BS 1363-3 Figure 5 standards

• Material hardness exceeds 50HRC

• Low thermal expansion coefficient ensures stable dimensions and tolerances

• Meets standard requirements for gauge dimensions, tolerances, material, hardness, and surface roughness

• All specified dimensions are in millimetres

• Features a true profile (TP) with a radius of 15.088 and a tolerance zone of 0.100 wide (±0.050 from the TP), with the contour blending smoothly with the sides

• Corners may be relieved up to a width of 0.8 as specified

• Includes a 30° optional slot

• Permissible to be fabricated in multiple component parts, provided assembly meets the shown dimension requirements

• Incorporates dimensional parameters such as 11.5, 10.5, 55, 3.36, 13.0*2 mm (all round), 25.40, 23.25, 23.23, 25.37, 33, 22.23, 4.20, 4.18, 22.21, 6.40, 6.35, 3.2, 7.79, 14.44, 14.43

Test Procedures:

• Prepare the adaptor pin test specimen, ensuring it is clean, undamaged, and free from any deformities that may affect test results.

• Familiarize yourself with the dimensional requirements and tolerance ranges specified in BS 1363-3 Figure 5 (including relevant clauses).

• Position the adaptor pin specimen into the gauge in accordance with the designated assembly method, ensuring proper alignment.

• Inspect the relative position of the pin using the gauge’s precision reference features to confirm compliance with standard specifications.

• Measure the pin length using the gauge’s calibrated measurement points, verifying it falls within the acceptable tolerance range.

• Evaluate the fit of the pin’s joint surface with the plug by checking for gaps, misalignment, or non-conformities against the gauge’s reference contours.

• Verify the specimen’s conformance to the true profile (TP) requirements, including the radius and tolerance zone specifications.

• Record all test data, including dimensional measurements and fit evaluations.

• Compare the recorded results with BS 1363-3 Figure 5 criteria to determine if the adaptor pin meets the standard’s requirements.

Applications:

• Compliance testing of adaptor pins to verify conformance with BS 1363-3 Figure 5 standards.

• Quality control on production lines for plugs, sockets, and adaptors to ensure consistent pin dimensions and fit.

• R&D activities in the electronics and electrical appliance industries for optimizing adaptor pin design.

• Third-party testing and certification services to validate product compliance with BS 1363-3 specifications.

• Quality assurance processes in manufacturing facilities specializing in plugs, sockets, adaptors, and related electrical components.

Gauge for Adaptor Pins with BS 1363-3 Figure 5