Product No: XD-150LS

The XD-150LS xenon lamp aging and weather resistance test chamber is an important means for screening formulations and optimizing product compositions during the scientific research and production process. It is also an important part of product quality inspection. Applied materials such as coatings, plastics, geotextiles, textiles, fuels, aluminum-plastic panels, as well as automotive safety glass, automotive interior parts, exterior parts, and other products are required by relevant standards to undergo weather resistance tests.

The main factors causing material aging are sunlight, temperature, and humidity. The xenon lamp aging and weather resistance test chamber can simulate sunlight, rainwater, and dew. The materials to be tested are placed in a cyclic program of alternating illumination and moisture at a certain temperature for testing. It can reproduce the damages that occur outdoors in several months or even several years within just a few days or weeks.

The xenon lamp accelerated weathering test chamber uses a xenon arc lamp that simulates the solar spectrum to reproduce the destructive light waves existing in different environments. It can provide corresponding environmental simulation and accelerated test basis for scientific research, product development, and quality control. It can be used for the selection of new materials, the improvement of existing materials, or the evaluation of changes in durability after the composition of materials is altered. It can effectively simulate the changes that materials undergo when exposed to sunlight under different environmental conditions.

Reference Standards:

| Standard No. | Standard Name |

| ISO 4892-2 | Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon – arc lamp |

| ISO 11341 | Paint and varnishes – Artificial weathering and exposure to artificial radiation – Exposure to filtered xenon – arc radiation |

| ASTM G155 | Standard Practice for Operating Xenon – Arc Test Apparatus for Exposure of Non – Metallic Materials |

| ASTM D3424 | Standard Test Method for Light Resistance of Paper and Paperboard |

| ASTM D2565 | Standard Practice for Accelerated Aging of Plastics Using Xenon – Arc Apparatus |

| AATCC TM 169 | Textile Colorfastness to Artificial Light: Xenon – Arc Exposure |

| SAE J2412 | Accelerated Exposure of Interior Automotive Trim Components Using a Controlled Irradiance Xenon – Arc Apparatus |

| SAE J2527 | Accelerated Exposure of Exterior Automotive Materials Using a Controlled Irradiance Xenon – Arc Apparatus |

| IEC 68-2-9 | Basic environmental testing procedures – Part 2: Tests – Test Sa: Guidance on solar radiation testing |

Specifications:

| LISUN Model | XD-150LS | XD-80LS | XD-80LF | XD-010LF | XD-010LS |

| Chamber Dimension | |||||

| Internal Dimensions(D*W*H) | 500*600*500mm | 800*800*800mm | 1000*1000*1000mm | ||

| External Dimensions(D*W*H) | 1030*1130*1900mm | 1430*1230*2000mm | 1730*1430*2100mm | ||

| Temperature | |||||

| Temperature range in the chamber | RT~80℃ | ||||

| Black Panel Temperature | 45~85℃ Adjustable | ||||

| Temperature Fluctuation | ≤±0.5℃ | ||||

| Temperature Deviation | ±2℃(With the light off) | ||||

| Temperature Uniformity | ≤2℃ | ||||

| Heating Power | 4KW | ||||

| Humidity | |||||

| Humidity Range | 20~95%R.H | ||||

| Humidity Fluctuation | +2%, -3%R.H | ||||

| Humidity Deviation | ≤±3%R.H | ||||

| Humidifying Power | About 2KW | ||||

| Illumination | |||||

| Irradiance of xenon light source | 0.30~0.57W/m² (at 340nm) adjustable; 0.66~1.22W/m² (at 420nm) adjustable; 35~70W/m² (300~400nm) adjustable; 300~800W/m² (300~800nm) adjustable; 650~1200W/m² (300~800nm) adjustable | ||||

| Xenon Lamp Spectrum Wavelength | 280~800nm | ||||

| Illumination period is continuously adjustable | 1~999h、m、s | ||||

| Irradiance Probe |

Irradiance measurement range:0.1~5,000W/m²; |

||||

| Xenon Lamp Power | One xenon lamp/Total 1.8KW | Two xenon lamps/Total 3.6KW | One xenon lamp/Total 6.5KW | Three xenon lamps/Total 5.4KW | |

| Cooling Method of Xenon Lamp | Air cooling | Water cooling | Air cooling | ||

| Rain Simulation Function | |||||

| Rainfall Time | 1~9,999mins(Adjustable) | ||||

| Rainfall Cycle | 1~240mins(Adjustable) | ||||

| Others | |||||

| The distance between the center and the sample rack | 300~500mm(Adjustable) | ||||

| Temperature-Humidity-Irradiance Control Meter | 7-inch touch-screen meter | ||||

| Display and Control Functions | Temperature、Humidity、Irradiance、Spray | ||||

| The Life of the xenon Lamp Tube | 1,200hrs | ||||

| Power supply and total power | Three Phases 380V±10%、50Hz、6.5KW+ Total power of xenon lamp | ||||

Note: The corresponding quantity and power of xenon lamps can be customized according to the customer’s requirements!

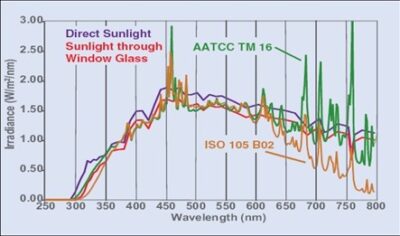

Xenon Lamp Spectrum Curve