Product No: JL-IWJ-010

The JL-IWJ-010 Cold Water Shock Test Chamber offers both Ice Water Splash and Ice Water Submersion test modes, supporting independent testing of either mode. It simulates the real-world environment of ice water splashing or submersion into heating systems and components when driving a car on wet winter roads. This equipment can reproduce typical failure modes such as mechanical cracking and sealing failure caused by differences in the coefficients of thermal expansion of materials. It is suitable for raw materials and components in the electronics, electrical engineering, appliance and plastics industries, conducting reliability tests on cold resistance, heat resistance, ice water splash resistance, and ice water submersion resistance. Utilizing a precise temperature and humidity control and flow regulation system, it ensures stable and controllable test conditions, providing a suitable environmental simulation for the reliability testing of various raw materials and components.

Standards:

| Standards No. | Standards Name |

| ISO 16750-4:2023 Clause 5.4 Figure 7/8/9 | Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 4: Climatic loads |

| VW 80000:2019 | Requirements for electrical and electronic components in motor vehicles – Environmental conditions and test requirements |

| MBN LV 124-2:2016 | Test items, test conditions and test requirements for electrical and electronic components of vehicles with a gross weight of 3.5 tons or less |

| GB/T 28046.4-2011 条款5.4图4/5/6 | 道路车辆 电气及电子设备的环境条件和试验 第 4 部分:气候负荷 |

Specififations:

| LISUN Model | JL-IWJ-500 | JL-IWJ-010 |

| Inner Dimensions | 1400*1750*2200mm | 1650*1800*2300mm |

| External Dimensions | 800*800*800mm | 1000*1000*1000mm |

| Basket Dimensions | 400*400*400mm | 500*500*500mm |

| Inner Chamber Material | SUS316 stainless steel, corrosion resistant | |

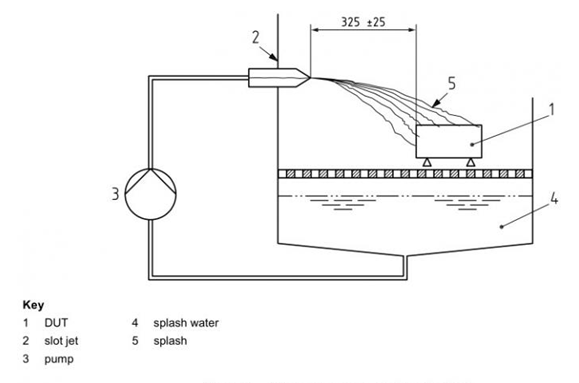

| Nozzle Parameters | One nozzle is located on the right side of the inner chamber (removable and washable); the distance between the nozzle and the sample is 325±25mm (adjustable). | |

| Spray Flow Rate | 3~4L/3s (equipped with a flow sensor and PID automatic constant flow control) | |

| Spray Circulation Control | Each cycle lasts 30 minutes (3 seconds of spraying, with intervals of 29 minutes and 57 seconds); the number of cycles is 100 (touchscreen setting). | |

| Cold Water Temperature Control | 0~+4℃ (Water circulation cooling method to ensure water temperature and uniformity of mixed water) | |

| Chamber Temperature | RT+10~150℃; cooling time ≤2.6℃/min, heating time ≤3.5℃/min | |

| Test Liquid Medium | Deionized water + 5% NaCl + 3% Arizona fine dust; Dust mixing method: Pipeline circulating water mixing. | |

| Test Sample Stage | Adjustable lifting basket, with a load capacity of 50kg | |

| Test Well of the Sample Under Test | A 100mm diameter test hole is provided on the left side, which can be used to connect an external power supply or signal cable to the object under test. | |

| Control System | 7-inch touchscreen + Panasonic PLC, automatic constant current and temperature control, displaying flow rate/temperature. | |

| Refrigeration/High Temperature System | French Tecumseh compressor (air-cooled condenser); long-shaft fan motor + 316 stainless steel impeller | |

| Circulatory System | Each component, including the ice water splash and the water tank flushing circulation system, is equipped with a custom-designed circulation pump to ensure stable flow rate and water temperature. | |

| Submersion Tank | Features automatic high and low water levels; circulating water agitation; and a sloping bottom design for easy cleaning and drainage. | |

| Automatic Cleaning Function | After testing, the pipeline and inner casing will be automatically cleaned (a handheld spray gun is required). | |

| Safety ProtectionFunction | Leakage protection, water shortage protection, short circuit protection, phase sequence protection, thermal overload protection | |

| Power Supply | Three-phase 380V/12KW/50Hz(60Hz can be customized) | Three-phase 380V/15KW/50Hz (60Hz can be customized) |

Typical Applications:

1. Automotive Electrical and Electronic Components: Ice water impact resistance testing for vehicle sensors, connectors, lamps, and power battery packs.

2. Electronic and Electrical Products: Ice water resistance verification for outdoor security equipment, industrial control instruments, and power tools.

3. Plastic Raw Materials and Components: Reliability testing of various plastic products in ice water environments.

4. New Energy Products: Low-temperature ice water environment resistance testing for outdoor charging piles, energy storage equipment, and photovoltaic modules.

5. Rail Transit Equipment: Ice water impact and immersion protection verification for train onboard electrical components and signaling devices.

6. Construction Machinery Components: Ice water resistance testing for electrical/sealing components of excavators, loaders, and other equipment.

7. Third-Party Testing Organizations: Climate load reliability certification testing services for various products.

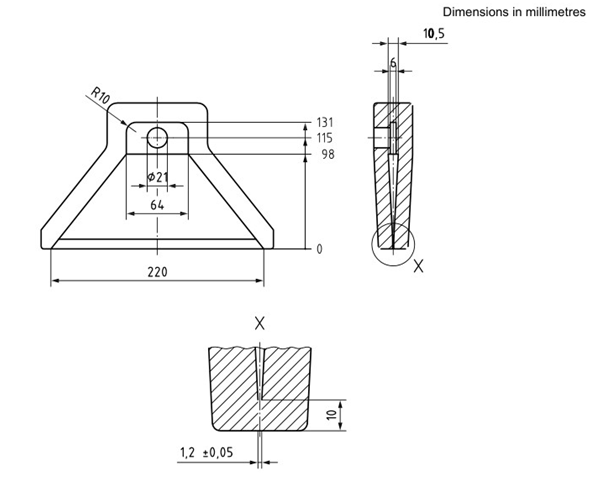

ISO 16750-4 Figure 4 Jet

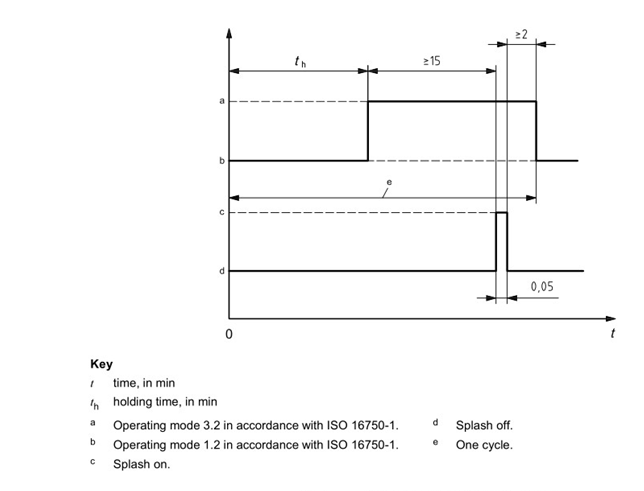

ISO 16750-4 Figure 5 Test Cycle for Splash water test

ISO 16750-4 Figure 6 Test set for Splash water test