Product No: ESD-RPB

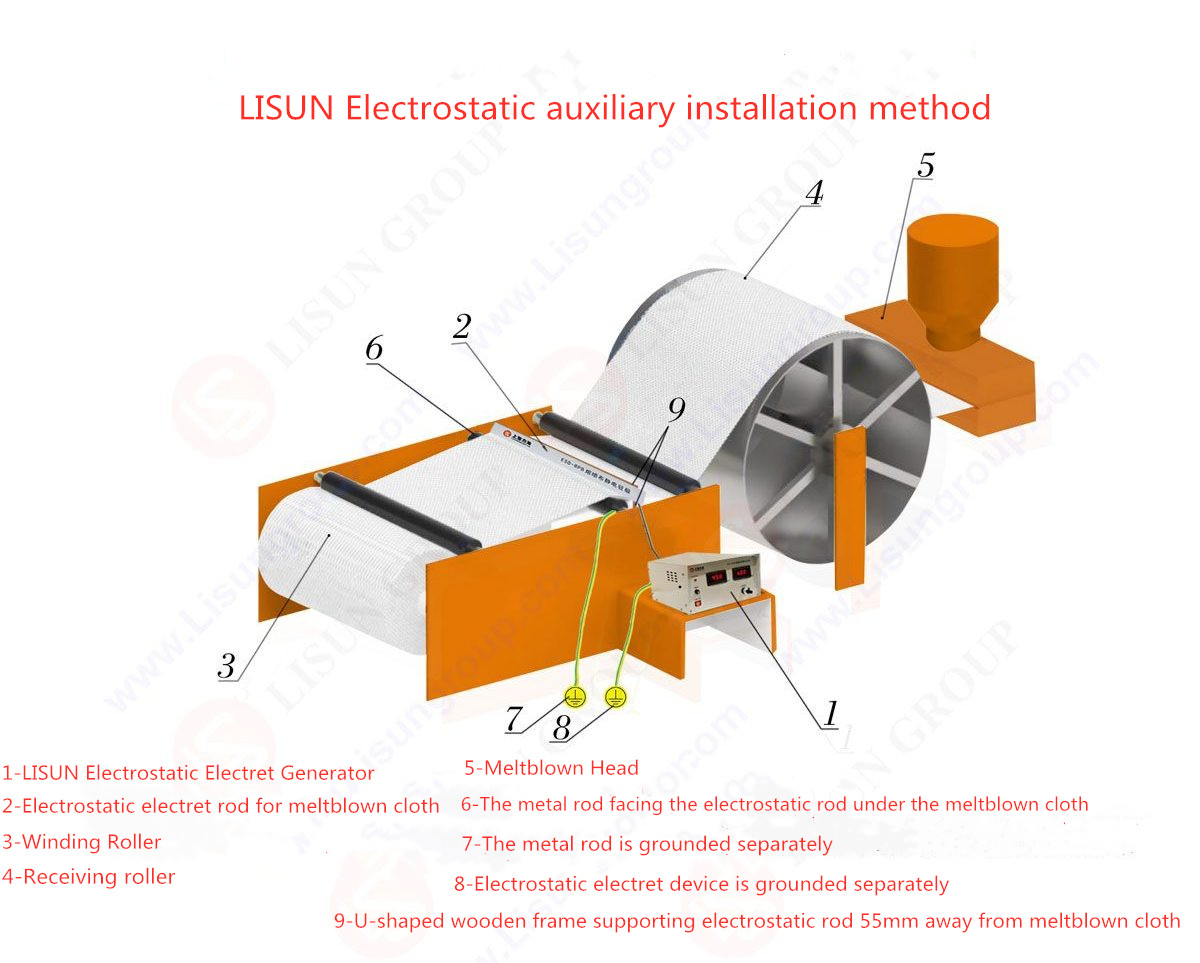

LISUN ESD-RPB Meltblown cloth electrostatic electret generator is composed of a pin-type electrostatic rod and a high-voltage DC power supply. The high-voltage DC power supply provides high voltage for ion emission, which causes the pin-type electrostatic bar to emit negative (positive) ions, and then charges objects such as melt-blown cloth. According to AATCC42, ASTM F1862-17, ASTM F2299-03 (2017), ASTM F2100-2019, BS EN14683-2019, BS EN 14387-2004+A1 2008, BS EN 136-1998, BS EN 140-1999, BS EN 143-2000 +C1-A1, BS EN 149-2001+A1, etc. It is widely used in non-woven fabrics, printing, film sticking, paint spraying, flocking, sorting and biological engineering and so on.

Function Instruction:

Because the filtration efficiency of ordinary melt-blown non-woven fabrics is less than 70%, it is not enough to mechanically block the three-dimensional aggregate of fibers that are purely based on melt-blown ultrafine fibers with fine fibers, small voids, and high porosity. Therefore, melt-blown filter materials generally need add electrostatic charge effect to the melt-blown cloth through electrostatic electret process, improve the filtration efficiency through the electrostatic methods, so that the filtration efficiency can reach to 99.9%, a thin layer can achieve the expected standard, and the respiratory resistance is still small.

The current electrostatic electret methods mainly include electrostatic spinning method, pin-type discharge method, triboelectric method, thermal polarization method, low energy electron beam bombardment method, etc. Among them, the pin-type discharge method is the best electrostatic electret method at present. In the pin-type discharge method, the melt-blown fiber web is charged by the corona discharge method of the electrostatic generator pin electrode (voltage is generally 5-60KV) before winding. When the high voltage is applied, the air below the pin tip generates corona ionization. The carrier ions are deposited on the surface of the melt-blown by the electric field. A part of the carrier ions will penetrate into the surface layer and be captured by the trap of the electret masterbatch, thus making the melt-blown an electret filter material.

Increasing the charge on the surface of the melt-blown fabric can be obtained through the electret treatment process of the corona discharge method. But for this electrostatic storage to not decay, the composition and structure of the melt-blown electret material are needed to facilitate charge retention. And by introducing additives with charge storage properties to generate charge traps to capture charge, can improve the charge storage capacity of electret materials. Therefore, compared with ordinary melt-blown production lines, the production of melt-blown production lines for air filtration materials needs to add electret masterbatch such as tourmaline particles to the production material polypropylene (PP), and increase its PFE or BFE filterability by means of electrostatic electrets.

Specifications:

1. High voltage DC power supply (With high frequency design)

| Model | ESD-RPB30KV | ESD-RPB60KV |

| Input voltage | 220V/50Hz(120V/60Hz customizable) | |

| Output voltage/current | 30KV/5mA | 60KV/2.5mA |

| Output polarity | Positive (+):ESD-RPB30KV Negative (-):ESD-RPB30KVM | Positive (+):ESD-RPB60KV Negative (-):ESD-RPB60KVM |

| Output port | 1 (Can be customized multiple) | |

| Dimension | 30*17*36cm (L*H*D) | |

| Weight | 12kg | |

2. Pin Type Corona Electrostatic Bar: The internal circuit is designed with functions such as preventing arc sparking and steady current, which fully guarantee the stability and uniformity of the current output of each needle.

| Model | ESD-BAR800 | ESD-BAR1200 | ESD-BAR1600 | ESD-BAR2000 |

| Effective length | 800mm | 1200mm | 1600mm | 2000mm |

| Actual length | 900mm | 1300mm | 1700mm | 2100mm |

| Static needle | Tungsten needles, needle spacing and needle diameter are designed by LISUN | |||

Note: Longer electrostatic bars can be customized according to the actual melt-blown fabric width; the effective length in the above table can be customized to extend 5-20mm according to requirements, and the actual length can be customized to extend 50-150mm according to requirements.

3. The Rack for Melt-blown Corona Electrostatic: Stainless steel shell, fully alumina roller designed by LISUN, used with high voltage DC power supply and pin-type electrostatic bar. Can support up to four Electrostatic Electret Generators to work at the same time to ensure long-term static electricity.

| Model | ESD-RACK800 | ESD-RACK1200 | ESD-RACK1600 | ESD-RACK2000 |

| Effective width | 1000mm | 1400mm | 1800mm | 2200mm |

Note: The longer Rack for Melt-blown Corona Electrostatic can be customized according to the actual melt-blown width; the effective width in the above table can be customized to extend 50-150mm according to the requirements.